The Composition and Application of Harmonic Speed Reducers: Revolutionizing Precision Engineering

In the world of precision engineering, harmonic speed reducers stand out as a revolutionary component that has transformed various industries. From robotics to aerospace, these sophisticated devices have enabled advancements that were once deemed impossible. This article delves into the composition, working principles, and applications of harmonic speed reducers, shedding light on why they are crucial in modern technology.

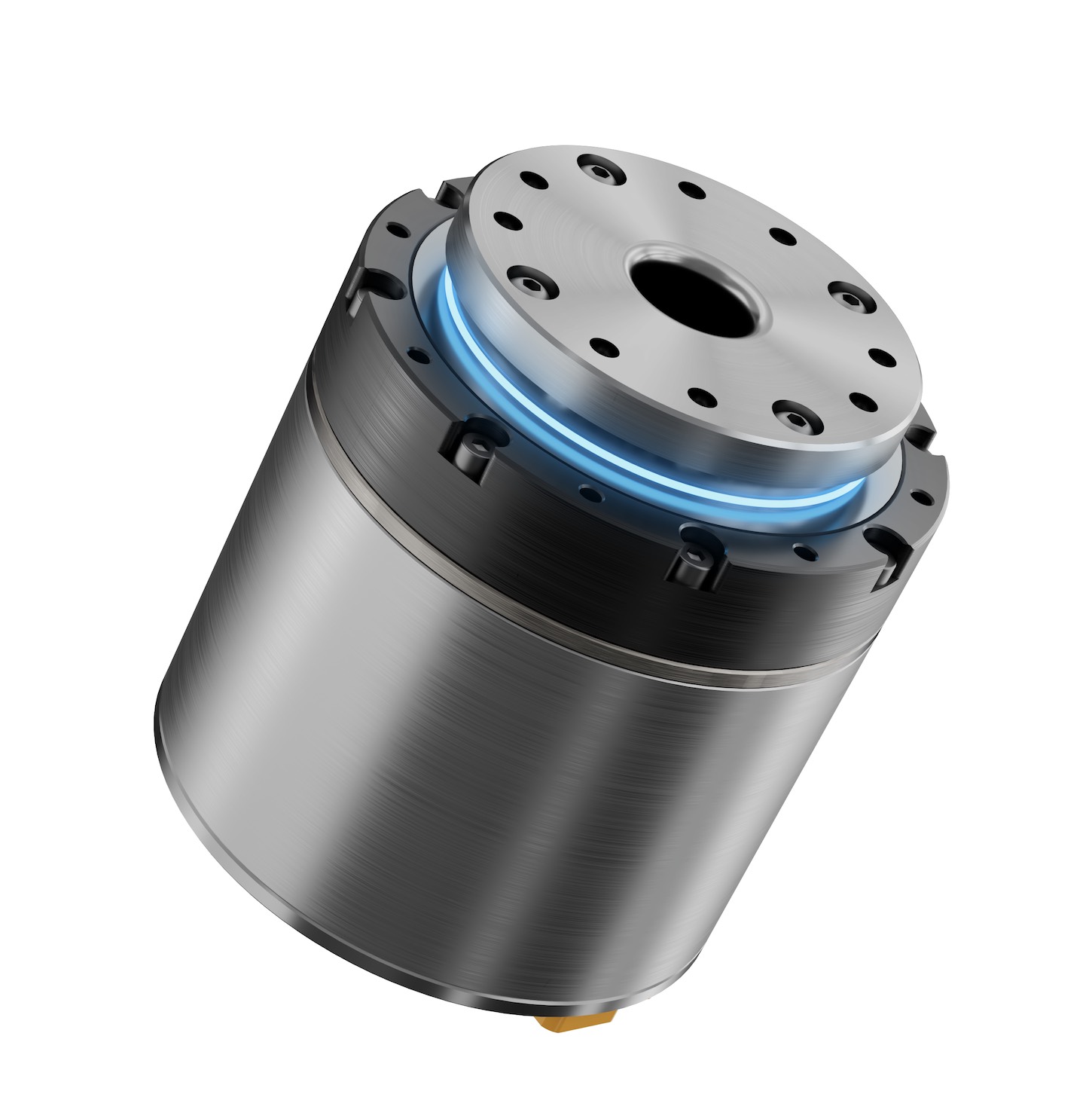

Composition of Harmonic Speed Reducers

Harmonic speed reducers, often referred to as harmonic drives, are a type of gear mechanism known for their high precision and efficiency. They typically consist of three main components:

The unique interaction between these components allows for the harmonic drive's distinctive characteristics, including zero backlash, high torque capacity, and exceptional positional accuracy.

The harmonic speed reducer operates on the principle of strain wave gearing.

Applications of Harmonic Speed Reducers

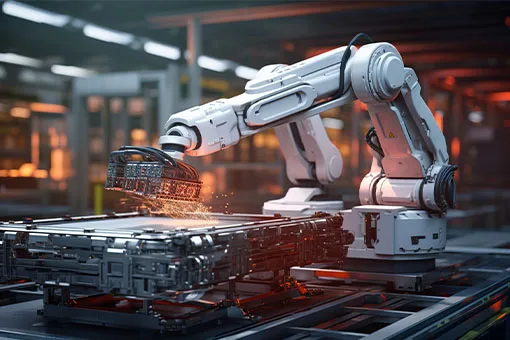

The exceptional characteristics of harmonic speed reducers make them indispensable in various high-precision applications:

Robotics: Harmonic drives are extensively used in robotic arms and joints due to their precise motion control and compact design. They enable robots to perform delicate tasks with high accuracy and repeatability.

Aerospace: in the aerospace i ndustry, where reliability and precision are paramount, harmonic speed reducers are utilized in satellite positioning systems and aircraft control surfaces.

Medical Equipment: Medical devices, such as surgical robots and imaging systems, benefit from the smooth and accurate motion provided by harmonic drives.

Industrial Automation: Harmonic speed reducers play a critical role in automated manufacturing systems, including CNC machines and assembly lines, by ensuring precise control and high torque output.

Optics and Photonics: These drives are also employed in optical equipment for precise positioning of lenses and mirrors, essential for high-resolution imaging and laser applications.

Advantages of Harmonic Speed Reducers

The widespread adoption of harmonic speed reducers across various industries can be attributed to their numerous advantages:

Compact and Lightweight: The compact design and lightweight nature make them ideal for applications where space and weight are constraints.

High Torque Density: Despite their small size, harmonic drives can handle high torque loads, making them suitable for demanding applications.

Smooth Operation: The continuous tooth engagement results in smooth and quiet operation, reducing wear and tear.

Harmonic speed reducers have revolutionized the field of precision engineering with their innovative design and exceptional performance. Their ability to provide high precision, compactness, and high torque in a lightweight package makes them indispensable in modern technology. As industries continue to advance, the demand for these remarkable devices is only set to grow, driving further innovation and application in various fields.

References

- Musser, C. W. (1957). Strain Wave Gearing. US Patent 2,906,143.

- Harmonic Drive LLC. (2023). Technical Overview of Harmonic Drive® Precision Gearing. Retrieved from Harmonic Drive LLC

- Zivkovic, A., & Manojlovic, L. (2018). Application of Harmonic Drive Gearings in Robotics. International Journal of Advanced Robotic Systems, 15(2), 1-10. doi:10.1177/1729881418765070

- Singh, R., & Sidhu, T. (2019). Advancements in Strain Wave Gearing for Aerospace Applications. Journal of Aerospace Engineering, 32(3), 04019012. doi:10.1061/(ASCE)AS.1943-5525.0000990