The Differences between Oldham Coupling Cam and Rigid Cam: Structural and Performance Analysis

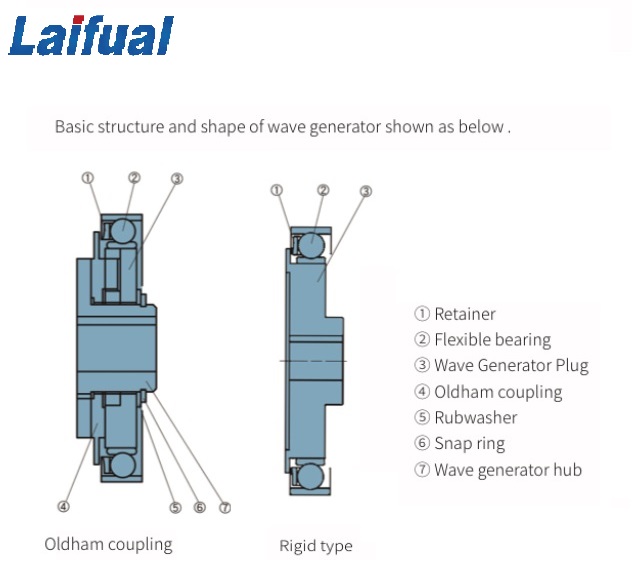

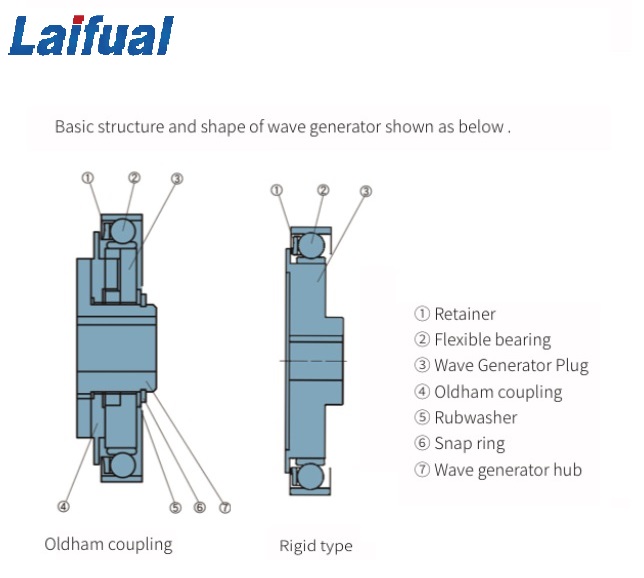

In the world of mechanical transmission systems, the precise interaction between components like wave generators, reducers, and cams plays a crucial role in determining the overall performance and longevity of the system. Two notable cam designs commonly used in harmonic drive systems are the Oldham Coupling Cam (often referred to as the Cross Slider) and the Rigid Cam (commonly known as the Integrated Cam). These two designs, though serving similar functions in power transmission, differ significantly in their structural characteristics and operational capabilities.

The Oldham Coupling Cam, known for its ability to automatically adjust the concentricity between the wave generator and the reducer, offers flexibility in maintaining alignment over time. However, due to the inherent backlash between its rollers, long-term operation can lead to increased play, potentially affecting precision and stability.

On the other hand, the Rigid Cam design does not feature this automatic concentricity adjustment. With advancements in machining precision, it is now possible to achieve and maintain high levels of alignment between the cam and the reducer, ensuring stable and consistent performance over extended periods without the need for real-time adjustments.

This article aims to delve into the fundamental differences between the Oldham Coupling Cam and the Rigid Cam, exploring their design features, performance characteristics, advantages, and limitations. By understanding these differences, engineers and designers can make more informed decisions when selecting the most suitable cam type for their specific applications.

Basic Concepts of the Oldham Coupling Cam and Rigid Cam

The Oldham Coupling Cam (often referred to as the Cross Slider) and the Rigid Cam are two distinct designs used in harmonic drive systems, playing a critical role in ensuring the efficient transfer of power and precise motion control in various mechanical applications.

Oldham Coupling Cam (Cross Slider)

The Oldham Coupling Cam features a unique design that allows automatic adjustment of the concentricity between the wave generator and the reducer. This design is particularly useful in systems where slight misalignments could lead to inefficiencies or wear. The adjustment range is typically within 0.05mm, ensuring that the components remain aligned during operation. However, a notable disadvantage is the presence of backlash between the rollers. Over time, this backlash can gradually increase, which may negatively impact performance and lead to a reduction in system precision.

Rigid Cam (Integrated Cam)

The Rigid Cam, in contrast, has a fixed structure where the cam and the reducer are precisely aligned from the outset, without any inherent mechanism for real-time concentricity adjustment. With modern advancements in machining technology, the precision of the cam and reducer alignment is greatly enhanced, ensuring that they remain concentric throughout the system’s lifespan. This results in more stable performance, particularly in high-precision applications, where maintaining a tight alignment is crucial.

Both designs have their advantages and limitations. The Oldham Coupling Cam is well-suited for applications requiring flexibility in alignment adjustments, while the Rigid Cam is ideal for systems where long-term precision and stability are paramount.

Understanding these basic concepts helps in selecting the right cam system based on the specific needs of the application, whether it's for flexibility or high-precision performance.

Design Structure and Working Principle Comparison

When comparing the Oldham Coupling Cam (Cross Slider) and the Rigid Cam, it is essential to explore their design structures and working principles, as these directly influence their performance, longevity, and suitability for various applications in harmonic drive systems.

Oldham Coupling Cam Design Structure

The Oldham Coupling Cam is characterized by its ability to adjust the concentricity between the wave generator and the reducer automatically. This is achieved through a set of sliding blocks that are positioned between the wave generator and the cam. The sliding blocks allow for fine adjustments, typically within a range of 0.05mm, to ensure that both components remain aligned. This feature makes the Oldham Coupling Cam ideal for systems where alignment may fluctuate due to operational conditions or tolerances.

However, the design also introduces some challenges. The sliding blocks create a small gap or backlash between the components. Over time, this backlash can increase, resulting in a gradual loss of precision and efficiency. As the system ages, the increased gap can lead to a decrease in performance, especially in high-torque or high-precision applications.

Rigid Cam Design Structure

In contrast, the Rigid Cam has a fixed and tightly integrated structure. This design does not incorporate any mechanisms for real-time concentricity adjustment. Instead, the cam and reducer are meticulously aligned during the manufacturing process, leveraging modern machining precision to achieve an optimal fit. This rigid structure ensures that the components remain concentric throughout the operational lifespan, making it highly suitable for systems that demand consistent alignment and high-precision performance.

While the Rigid Cam lacks the flexibility of the Oldham Coupling Cam in terms of automatic adjustment, its stability and resistance to backlash make it more reliable for long-term use in high-performance systems. The absence of gaps between components reduces the likelihood of precision degradation over time, providing greater efficiency in systems requiring minimal error margins.

Working Principles: A Comparison

- Oldham Coupling Cam: The automatic adjustment mechanism between the wave generator and reducer allows for flexible operation, but the trade-off is the potential for backlash and performance degradation as the system ages.

- Rigid Cam: By maintaining a fixed alignment, the Rigid Cam ensures constant concentricity, making it ideal for applications where long-term precision is crucial, but without the ability to self-adjust for misalignment.

Understanding these design structures and working principles helps in choosing the right cam system based on the specific operational requirements. For systems that require adaptability and flexibility, the Oldham Coupling Cam offers distinct advantages, while the Rigid Cam is best suited for high-precision, long-term stability applications.

Performance Comparison: Oldham Coupling Cam vs. Rigid Cam

When evaluating the performance of the Oldham Coupling Cam and the Rigid Cam, it’s crucial to examine key factors such as concentricity, backlash, efficiency, and long-term stability. These elements are essential in determining which cam system is best suited for specific applications, whether flexibility, precision, or durability is the primary concern.

1. Concentricity and Adjustment

-

Oldham Coupling Cam: One of the standout features of the Oldham Coupling Cam is its ability to automatically adjust the concentricity between the wave generator and the reducer. This self-adjustment mechanism allows the system to maintain optimal alignment even as slight misalignments or wear may occur over time. The adjustment range is typically around 0.05mm, which ensures that the cam and reducer continue to operate smoothly despite any minor shifts in alignment.

However, while this automatic adjustment is beneficial in maintaining performance during initial operation, it comes at a cost. The Oldham Coupling Cam relies on backlash between the sliding blocks, which can increase over time due to the wear of these components. As the backlash expands, the precision of the system deteriorates, reducing the overall efficiency and performance. For applications that experience frequent operational changes or require adaptability, this feature can be advantageous in the short term, but it may not be ideal for systems that require long-term accuracy.

-

Rigid Cam: The Rigid Cam, by contrast, does not feature any automatic concentricity adjustment. Instead, it is manufactured with high precision to ensure that the cam and reducer are perfectly aligned from the outset. Machining technology today allows for incredibly tight tolerances, ensuring that the cam and reducer remain concentric over time without the need for further adjustments. This results in greater precision and stability, particularly in systems that demand long-term performance without the need for realignment.

The absence of automatic adjustment means that the Rigid Cam is highly reliable in systems that require consistent alignment. However, its rigidity also means that it lacks the flexibility to accommodate slight misalignments, making it less adaptable compared to the Oldham Coupling Cam in some use cases.

2. Backlash and Wear

-

Oldham Coupling Cam: Due to the sliding block design, the Oldham Coupling Cam is susceptible to backlash, especially with extended use. Backlash refers to the slight gap that exists between the sliding blocks, which can cause a loss of motion accuracy and decrease system efficiency. Over time, the sliding blocks wear down, causing the backlash to grow, leading to a gradual loss of precision and reduced operational efficiency.

This issue can be mitigated to some extent by regular maintenance, but for applications that require high precision and minimal tolerance for error, this increased backlash can be a significant drawback.

-

Rigid Cam: In contrast, the Rigid Cam is designed to maintain minimal play between components, which translates to a much lower likelihood of backlash. This contributes to greater long-term stability and precision, as there is no gradual degradation in the system’s alignment. The precision of the Rigid Cam ensures consistent performance without the need for adjustments, even after prolonged use.

3. Efficiency and Energy Loss

-

Oldham Coupling Cam: While the Oldham Coupling Cam can maintain alignment during normal operations, the increasing backlash over time can lead to increased friction and energy loss. As the gap between components widens, the efficiency of power transmission decreases. This is especially problematic in systems where energy efficiency is critical.

-

Rigid Cam: The Rigid Cam, with its precise fit and minimal backlash, provides a more efficient power transmission. With better alignment and fewer losses due to friction or misalignment, the Rigid Cam is particularly advantageous in applications where high efficiency is a priority, such as in high-precision machinery or robotics.

4. Long-Term Performance

-

Oldham Coupling Cam: In the long run, the Oldham Coupling Cam may experience a decline in performance due to increasing backlash and wear. As the system operates over time, the precision required for high-performance tasks may diminish, leading to potential issues in accuracy, efficiency, and overall functionality. Thus, while it is suitable for certain applications where adaptability is required, it is less ideal for applications that demand sustained high precision.

-

Rigid Cam: The Rigid Cam excels in long-term performance, especially in systems where consistent precision is paramount. Since it does not rely on sliding components that wear out over time, the Rigid Cam maintains its performance over long durations. This makes it a better choice for high-precision systems that require stable and accurate operation, such as in aerospace, robotics, or medical devices.

Conclusion: Which Cam Offers Better Performance?

- Oldham Coupling Cam: Best suited for applications requiring flexibility and adaptability in alignment, but with some compromise in long-term precision due to backlash.

- Rigid Cam: The Rigid Cam offers superior long-term performance, higher precision, and better efficiency with minimal wear and backlash, making it the preferred choice for high-precision, high-stability applications.

In summary, the choice between the Oldham Coupling Cam and the Rigid Cam depends on the specific requirements of the application, including factors such as precision, adaptability, long-term performance, and efficiency. For systems that need real-time adjustments and are less sensitive to precision degradation, the Oldham Coupling Cam is a solid choice. However, for applications demanding sustained accuracy and reliability, the Rigid Cam is the optimal solution.

Advantages, Disadvantages, and Suitable Applications of Oldham Coupling Cam vs. Rigid Cam

When choosing between the Oldham Coupling Cam (Cross Slider) and the Rigid Cam, it’s essential to evaluate their respective advantages and disadvantages, as well as the types of applications where each design excels.

Advantages and Disadvantages

The Oldham Coupling Cam offers a significant advantage in its ability to automatically adjust the concentricity between the wave generator and the reducer, making it ideal for systems where alignment might fluctuate or need real-time adjustments. The self-adjustment mechanism ensures that minor misalignments are corrected during operation, which is beneficial for applications where flexibility is crucial. However, a significant drawback is the backlash between the sliding blocks. Over time, this backlash can gradually increase, reducing the overall precision and efficiency of the system. As the system ages, the backlash effect becomes more pronounced, potentially compromising the long-term performance of the system.

On the other hand, the Rigid Cam excels in maintaining long-term precision with minimal backlash due to its tightly integrated design. Since it does not rely on adjustments or sliding components, it is less prone to wear, ensuring consistent performance and high stability. The major disadvantage of the Rigid Cam is the lack of flexibility in accommodating minor misalignments. If the alignment is off during the initial setup, the system may face performance issues over time, and realignment would require manual intervention. Additionally, its lack of adjustment features makes it less adaptable to systems where alignment fluctuations are common.

Suitable Applications

The Oldham Coupling Cam is well-suited for applications requiring flexibility and dynamic adjustments. It is a good choice for systems that experience frequent realignment due to operational changes, such as in less precision-sensitive machinery or where system tolerances are more lenient. Industries like automotive manufacturing or low-precision automation might benefit from this cam design, where adaptability and cost-effectiveness are prioritized over long-term precision.

In contrast, the Rigid Cam is best suited for high-precision applications where long-term performance and stability are crucial. It is ideal for robotics, aerospace, medical devices, and high-performance machinery, where maintaining tight tolerances and minimal error margins over an extended period is critical. The Rigid Cam’s consistent performance and durability make it the preferred choice for systems that demand high efficiency and reliability without the need for frequent realignment.

Ultimately, the decision between the Oldham Coupling Cam and the Rigid Cam depends on the application’s requirements for flexibility, precision, and long-term stability. Understanding the advantages, disadvantages, and the operational environment is essential in selecting the most suitable cam system for optimal performance.

Customized Solutions by Laifual: Tailoring Cam Designs to Your Needs

At Laifual, we understand that every industrial application has unique requirements. Leveraging our in-house R&D expertise and vertically integrated production facilities, we offer customized solutions for both Oldham Coupling Cams and Rigid Cams. Our engineering team collaborates closely with clients to optimize cam designs based on specific operational demands—whether prioritizing short-term alignment flexibility or long-term precision stability. With full control over manufacturing processes, from prototyping to final assembly, we ensure seamless integration of these components into harmonic drive systems across industries such as robotics, aerospace, and advanced automation. This capability allows us to deliver not only standardized products but also bespoke designs that align perfectly with your performance, durability, and cost-efficiency goals.

Conclusion and Recommendations

The comparison between the Oldham Coupling Cam (Cross Slider) and the Rigid Cam highlights their unique strengths and limitations. The Oldham Coupling Cam offers flexibility with automatic concentricity adjustment, making it suitable for systems where misalignments are common. However, its susceptibility to backlash can reduce precision over time, limiting its effectiveness in long-term, high-precision applications.

In contrast, the Rigid Cam provides stable performance and long-term precision, with minimal backlash, making it ideal for high-precision systems that require consistent efficiency. Its lack of self-adjustment limits its adaptability, but its reliability in maintaining alignment over time makes it perfect for industries like robotics, aerospace, and medical devices.

Recommendations:

- For systems requiring alignment flexibility and short-term adaptability, the Oldham Coupling Cam is a good choice, especially in automotive or low-precision automation.

- For high-precision, long-term stability, the Rigid Cam is recommended, particularly in fields like robotics, aerospace, or medical devices, where maintaining tight tolerances is essential.

Choosing between the two depends on whether flexibility or long-term precision is more important for the specific application.