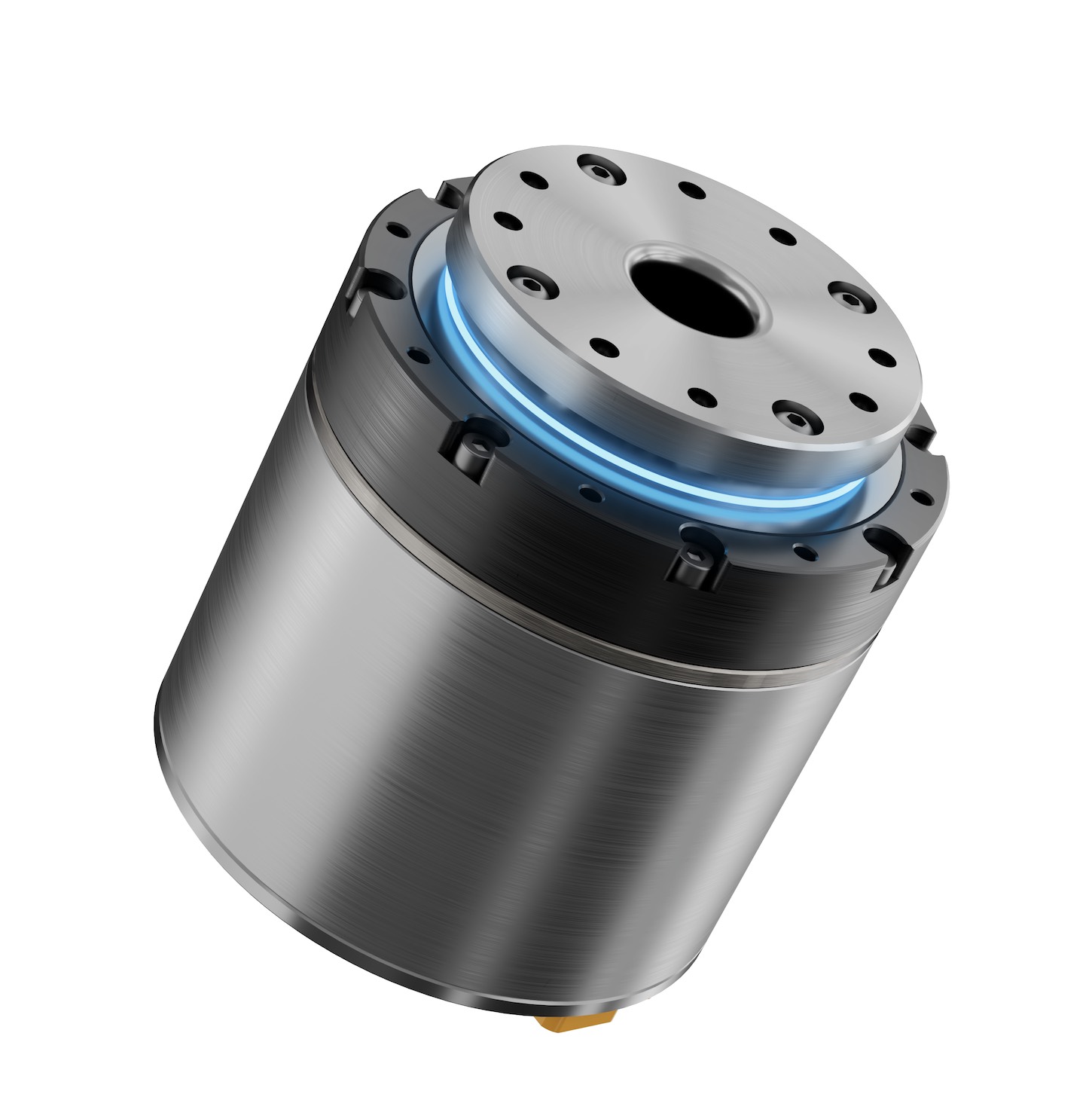

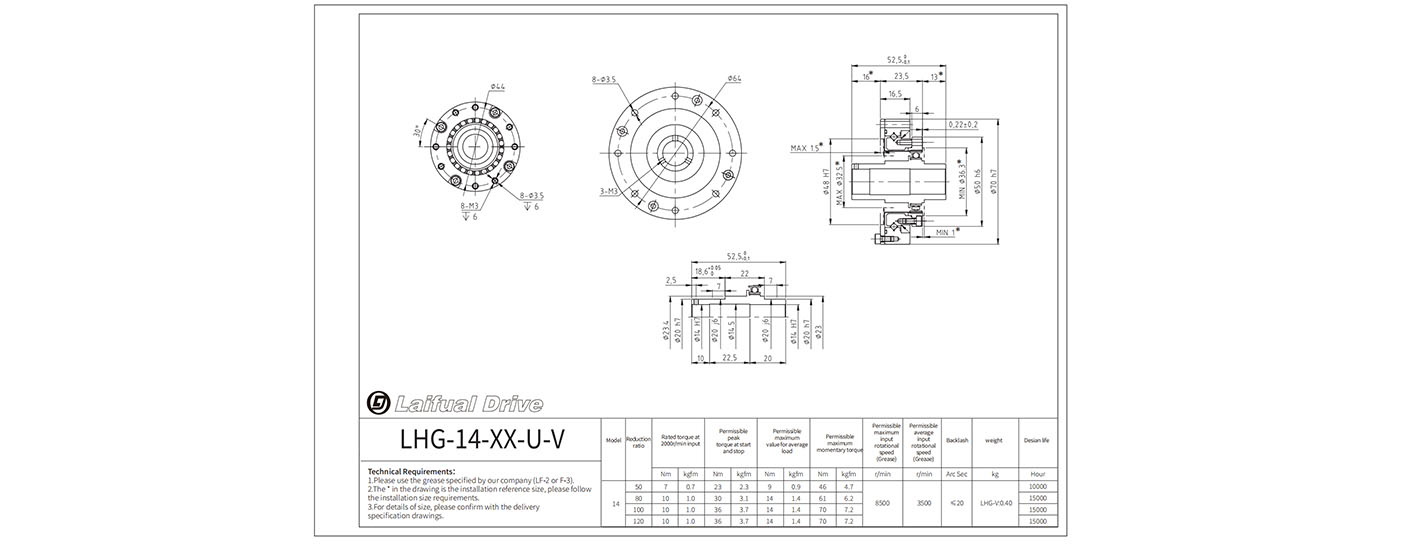

LHG High Torque Harmonic Gearbox

LHG series harmonic reducer features a hollow flanged barrel structure, with a compact overall design, developed specifically for high-torque applications.

Key Features

- Flat design, large diameter, hollow shaft

- Compact and concise design

- Zero backlash

- Input and output coaxial

- Excellent positional accuracy and repeatability.

- Product Description

- Specifications

- Product Video

- Application

- FAQ

- Download

Product Description

The LHG series is a product of the company's pursuit of high load capacity and reliability. It offers a 30% higher torque capacity compared to standard products, ensuring superior performance in demanding applications. With a 43% increase in service life, the LHG series provides enhanced reliability and longevity, minimizing downtime and maintenance costs.

Advantages

LHG-I/II:

More Compact Design: Offers a compact form factor for space-efficient integration.

Two Connection Options: Provides flexibility in connection methods. Direct Motor Connection: Allows the motor to be connected directly to the gearbox for simplified installation.

LHG-III High Reliability Harmonic drive Gearbox:

Large-Diameter Hollow Shaft Hole: Features a large-diameter hollow shaft hole in the middle of the wave generator cam for versatile applications.

Fully Sealed Structure: Ensures reliability and protection against environmental factors.

Easy Installation: Simplified installation process for convenience.

LHG-IV :

Suitable for Different Input Forms: Compatible with various input configurations for versatility.

Fully Sealed Structure: Provides protection and reliability in challenging environments.

Easy Installation: Streamlined installation process for user convenience.

LHG-V Large Speed Ratio Harmonic Gearbox:

Versatile Redesign Options: Users can freely redesign for lower weight and thinner thickness while maintaining consistent performance characteristics.

No Change in Performance: Despite redesigning, performance remains unaffected for reliable operation.

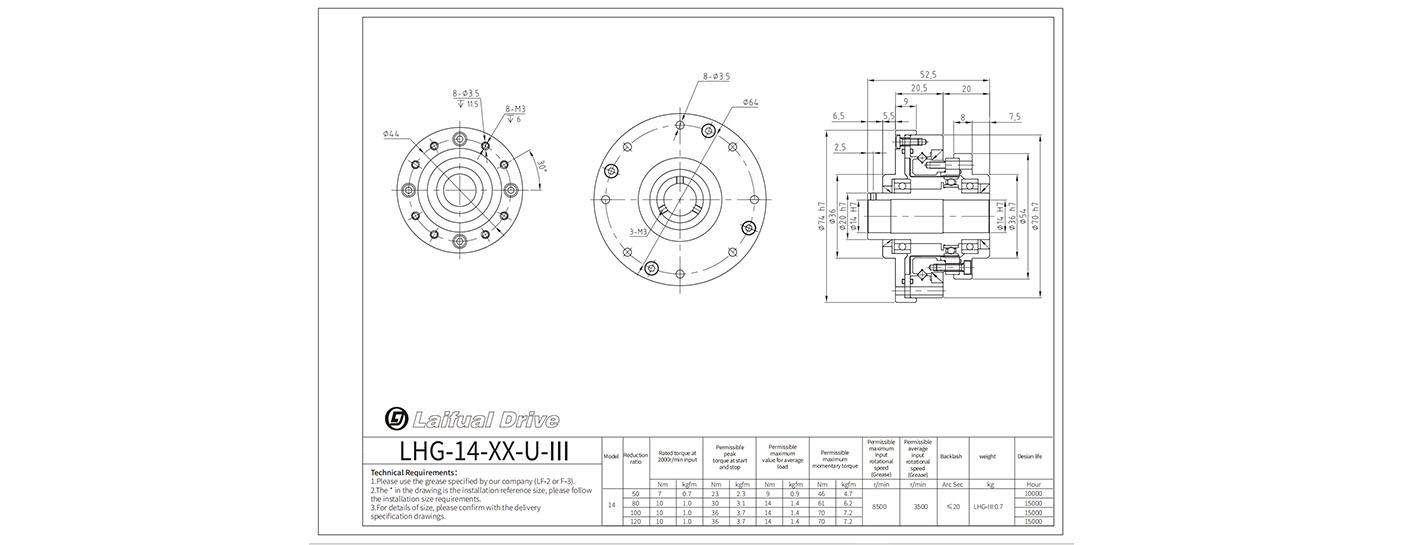

Specifications

Specification of LHG Rated parameters

| Model | Reduction ratio | Rated torque at 2000r/min input | Permissible peak torque at start and stop | Permissible maximum value for average load torque | Permissible maximum momentary torque | Permissible maximum input rotational speed | Permissible average input rotational speed | Backlash | Weight | Design life | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Grease | Grease | |||||||||||||

| Nm | kgfm | Nm | kgfm | Nm | kgfm | Nm | kgfm | r/min | r/min | Arc Sec | Kg | Hour | ||

| 14 | 50 | 7 | 0.7 | 23 | 2.3 | 9 | 0.9 | 46 | 4.7 | 8500 | 3500 | ≤20 | LHG-I/II:0.40 | 10000 |

| 80 | 10 | 1 | 30 | 3.1 | 14 | 1.4 | 61 | 6.2 | LHG-III:0.7 | 15000 | ||||

| 100 | 10 | 1 | 36 | 3.7 | 14 | 1.4 | 70 | 7.2 | LHG-IV:0.66 | 15000 | ||||

| 120 | 10 | 1 | 36 | 3.7 | 14 | 1.4 | 70 | 7.2 | LHG-V:0.40 | 15000 | ||||

| 17 | 50 | 21 | 2.1 | 44 | 4.5 | 34 | 3.4 | 91 | 9 | 7300 | 3500 | ≤20 | LHG-I/II:0.54 | 10000 |

| 80 | 29 | 2.9 | 56 | 5.7 | 35 | 3.6 | 113 | 12 | LHG-III:0.99 | 15000 | ||||

| 100 | 31 | 3.2 | 70 | 7.2 | 51 | 5.2 | 143 | 15 | LHG-IV:0.90 | 15000 | ||||

| 120 | 31 | 3.2 | 70 | 7.2 | 51 | 5.2 | 112 | 11 | LHG-V:0.62 | 15000 | ||||

| 20 | 50 | 33 | 3.3 | 73 | 7.4 | 44 | 4.5 | 127 | 13 | 6500 | 3500 | ≤20 | LHG-I/II:0.72 | 10000 |

| 80 | 44 | 4.5 | 96 | 9.8 | 61 | 6.2 | 165 | 17 | LHG-III:1.32 | 15000 | ||||

| 100 | 52 | 5.3 | 107 | 10.9 | 64 | 6.5 | 191 | 20 | LHG-IV:1.29 | 15000 | ||||

| 120 | 52 | 5.3 | 113 | 11.5 | 64 | 6.5 | 191 | 20 | LHG-V:0.82 | 15000 | ||||

| 160 | 52 | 5.3 | 120 | 12.2 | 64 | 6.5 | 191 | 20 | 15000 | |||||

| 25 | 50 | 51 | 5.2 | 127 | 13 | 72 | 7.3 | 242 | 25 | 5600 | 3500 | ≤20 | LHG-I/II:1.22 | 10000 |

| 80 | 82 | 8.4 | 178 | 18 | 113 | 12 | 332 | 34 | LHG-III:2.02 | 15000 | ||||

| 100 | 87 | 8.9 | 204 | 21 | 140 | 14 | 369 | 38 | LHG-IV:1.99 | 15000 | ||||

| 120 | 87 | 8.9 | 217 | 22 | 140 | 14 | 395 | 40 | LHG-V:1.40 | 15000 | ||||

| 32 | 50 | 99 | 10 | 281 | 29 | 140 | 14 | 497 | 51 | 4800 | 3500 | ≤20 | LHG-I/II:2.54 | 10000 |

| 80 | 153 | 16 | 395 | 40 | 217 | 22 | 738 | 75 | LHG-III:4.20 | 15000 | ||||

| 100 | 178 | 18 | 433 | 44 | 281 | 29 | 841 | 86 | LHG-IV:4.00 | 15000 | ||||

| 120 | 178 | 18 | 459 | 47 | 281 | 29 | 892 | 91 | LHG-V:2.70 | 15000 | ||||

| 40 | 50 | 178 | 18 | 523 | 53 | 255 | 26 | 892 | 91 | 4000 | 3000 | ≤20 | LHG-I/II:4.40 | 10000 |

| 80 | 268 | 27 | 675 | 69 | 369 | 38 | 1270 | 130 | LHG-III:7.20 | 15000 | ||||

| 100 | 345 | 35 | 738 | 75 | 484 | 49 | 1400 | 143 | LHG-IV:7.00 | 15000 | ||||

| 120 | 382 | 39 | 802 | 82 | 586 | 60 | 1530 | 156 | LHG-V:4.06 | 15000 | ||||

-

Composition of Harmonic Gear Reducer?

+Harmonic drive reducers (also known as strain wave gearbox/reducer) are increasingly widely used in aviation, aerospace, energy, navigation, shipbuilding, bionic machinery, commonly used ordnance, machine tools, instruments, electronic equipment, mining and metallurgy, transportation, lifting machinery, petrochemical machinery, textile machinery, agricultural machinery and medical equipment

-

Cycloidal vs Harmonic Drive?

+Harmonic drive reducers (also known as strain wave gearbox/reducer) are increasingly widely used in aviation, aerospace, energy, navigation, shipbuilding, bionic machinery, commonly used ordnance, machine tools, instruments, electronic equipment, mining and metallurgy, transportation, lifting machinery, petrochemical machinery, textile machinery, agricultural machinery and medical equipment

-

Characteristics of Harmonic Gear Reducer?

+Harmonic drive reducers (also known as strain wave gearbox/reducer) are increasingly widely used in aviation, aerospace, energy, navigation, shipbuilding, bionic machinery, commonly used ordnance, machine tools, instruments, electronic equipment, mining and metallurgy, transportation, lifting machinery, petrochemical machinery, textile machinery, agricultural machinery and medical equipment

-

Composition of Harmonic Gear Reducer?

+Harmonic drive reducers (also known as strain wave gearbox/reducer) are increasingly widely used in aviation, aerospace, energy, navigation, shipbuilding, bionic machinery, commonly used ordnance, machine tools, instruments, electronic equipment, mining and metallurgy, transportation, lifting machinery, petrochemical machinery, textile machinery, agricultural machinery and medical equipment

-

Cycloidal vs Harmonic Drive?

+Harmonic drive reducers (also known as strain wave gearbox/reducer) are increasingly widely used in aviation, aerospace, energy, navigation, shipbuilding, bionic machinery, commonly used ordnance, machine tools, instruments, electronic equipment, mining and metallurgy, transportation, lifting machinery, petrochemical machinery, textile machinery, agricultural machinery and medical equipment

-

Characteristics of Harmonic Gear Reducer?

+Harmonic drive reducers (also known as strain wave gearbox/reducer) are increasingly widely used in aviation, aerospace, energy, navigation, shipbuilding, bionic machinery, commonly used ordnance, machine tools, instruments, electronic equipment, mining and metallurgy, transportation, lifting machinery, petrochemical machinery, textile machinery, agricultural machinery and medical equipment

-

Cycloidal vs Harmonic Drive?

+Harmonic drive reducers (also known as strain wave gearbox/reducer) are increasingly widely used in aviation, aerospace, energy, navigation, shipbuilding, bionic machinery, commonly used ordnance, machine tools, instruments, electronic equipment, mining and metallurgy, transportation, lifting machinery, petrochemical machinery, textile machinery, agricultural machinery and medical equipment

Download

- LHG Series

- LHG-I Series

- LHG-II Series

- LHG-III Series

- LHG-IV Series

- LHG-V Series

- LHG-3D Series

Download

Download

NEED A ONE-STOP SOLUTION?

We believe in delivering excellent customer service and we are dedicated to our customers.

If you want to know more about our products, prices, and customized services, please contact us with more details, we will respond as soon as possible.