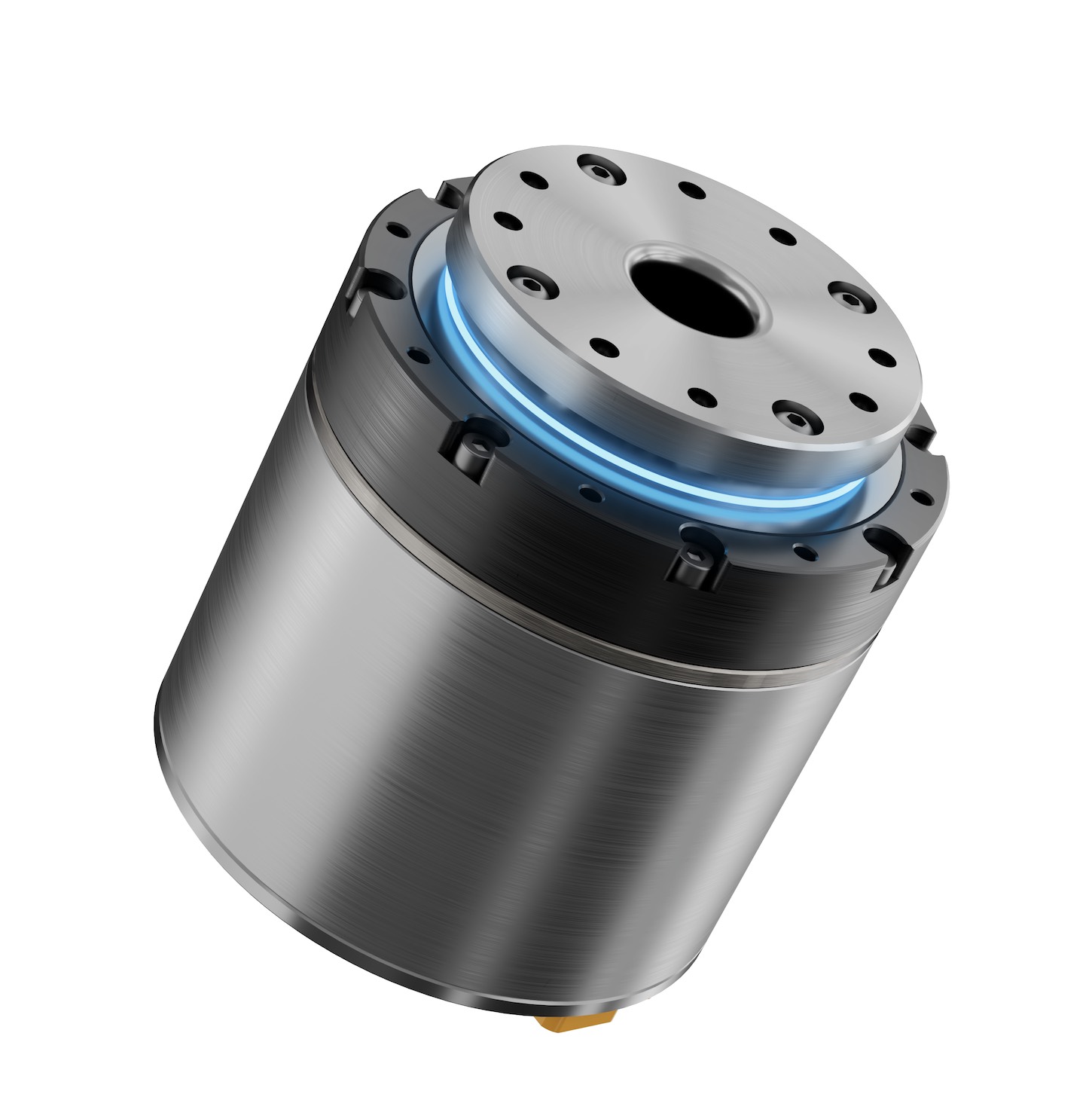

LSG High Torque Harmonic Drive

LSG series harmonic reducer employs a cup-shaped standard barrel structure for its flexible wheel, specifically developed for high-torque applications. With torque-bearing capacity surpassing 30% compared to the LSS series, it boasts an enhanced lifespan of over 43%, striving for high load capacity and reliability.

Key Features

- Cup type structure

- Compact and simple design

- No backlash

- Input and output coaxial

- Excellent positioning accuracy and rotation accuracy

- Product Description

- Specifications

- Application

- FAQ

- Download

Product Description

Compared with the LSS series, LSG harmonic reduction gear has the same dimension as LSS harmonic speed reducers, but we improved the hardness of flex spline, using different heat treatment methods. We also added the contacting area of gear parts to reach 30% higher torque capacity, so the service life of the LSG series of micro harmonic drive can also increase by 43%.

Advantages

Cup-shaped standard barrel structure for the flexible wheel, combined with high rigidity full roller cross bearings.

LS tooth profile design, utilizing self-developed CMP heat treatment process, and precision grinding with 1um track accuracy.

Compact and concise structural design, with zero backlash, direct motor connection, and easy installation.

Input and output coaxial

Excellent positional accuracy and repeatability..

Specifications

Specification of LSG Rated parameters

| Model | Reduction ratio | Rated torque at 2000r/min input | Permissible peak torque at start and stop | Permissible maximum value for average load torque | Permissible maximum momentary torque | Permissible maximum input rotational speed | Permissible average input rotational speed | Backlash | Weight | Design life | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Grease | Grease | |||||||||||||

| Nm | kgfm | Nm | kgfm | Nm | kgfm | Nm | kgfm | r/min | r/min | Arc Sec | Kg | Hour | ||

| 14 | 50 | 7 | 0.7 | 23 | 2.3 | 9 | 0.9 | 46 | 4.7 | 8500 | 3500 | ≦ 20 | LSG-I/II:0.51 | 10000 |

| 80 | 10 | 1 | 30 | 3.1 | 14 | 1.4 | 58[1] | 5.9[1] | 15000 | |||||

| 100 | 10 | 1 | 36 | 3.7 | 14 | 1.4 | 58[1] | 5.9[1] | 15000 | |||||

| 120 | 10 | 1 | 36 | 3.7 | 14 | 1.4 | 58[1] | 5.9[1] | 15000 | |||||

| 17 | 50 | 21 | 2.1 | 44 | 4.5 | 34 | 3.4 | 91 | 9 | 7300 | 3500 | ≦ 20 | LSG-I/II:0.67 | 10000 |

| 80 | 29 | 2.9 | 56 | 5.7 | 35 | 3.6 | 109[1] | 11[1] | 15000 | |||||

| 100 | 31 | 3.2 | 70 | 7.2 | 51 | 5.2 | 109[1] | 11[1] | 15000 | |||||

| 120 | 31 | 3.2 | 70 | 7.2 | 51 | 5.2 | 109[1] | 11[1] | 15000 | |||||

| 20 | 50 | 33 | 3.3 | 73 | 7.4 | 44 | 4.5 | 127 | 13 | 6500 | 3500 | ≦ 20 | LSG-I/II:0.96 | 10000 |

| 80 | 44 | 4.5 | 96 | 9.8 | 61 | 6.2 | 165 | 17 | 15000 | |||||

| 100 | 52 | 5.3 | 107 | 10.9 | 64 | 6.5 | 191 | 20 | 15000 | |||||

| 120 | 52 | 5.3 | 113 | 11.5 | 64 | 6.5 | 191 | 20 | 15000 | |||||

| 160 | 52 | 5.3 | 120 | 12.2 | 64 | 6.5 | 191 | 20 | 15000 | |||||

| 25 | 50 | 51 | 5.2 | 127 | 13 | 72 | 7.3 | 242 | 25 | 5600 | 3500 | ≦ 20 | LSG-I/II:1.46 | 10000 |

| 80 | 82 | 8.4 | 178 | 18 | 113 | 12 | 332 | 34 | 15000 | |||||

| 100 | 87 | 8.9 | 204 | 21 | 140 | 14 | 369 | 38 | 15000 | |||||

| 120 | 87 | 8.9 | 217 | 22 | 140 | 14 | 395 | 40 | 15000 | |||||

| 32 | 50 | 99 | 10 | 281 | 29 | 140 | 14 | 497 | 51 | 4800 | 3500 | ≦ 20 | LSG-I/II:3.11 | 10000 |

| 80 | 153 | 16 | 395 | 40 | 217 | 22 | 738 | 75 | 15000 | |||||

| 100 | 178 | 18 | 433 | 44 | 281 | 29 | 841 | 86 | 15000 | |||||

| 120 | 178 | 18 | 459 | 47 | 281 | 29 | 892 | 91 | 15000 | |||||

| 40 | 50 | 178 | 18 | 523 | 53 | 255 | 26 | 892 | 91 | 4000 | 3000 | ≦ 20 | LSG-I/II:4.6 | 10000 |

| 80 | 268 | 27 | 675 | 69 | 369 | 38 | 1270 | 130 | 15000 | |||||

| 100 | 345 | 35 | 738 | 75 | 484 | 49 | 1400 | 143 | 15000 | |||||

| 120 | 382 | 39 | 802 | 82 | 586 | 60 | 1510[1] | 154[1] | 15000 | |||||

| [1]The permissible maximum torque is limited by the driving torque of the coupling screw at the output end | ||||||||||||||

-

What is a harmonic drive box?

+A harmonic drive box is a type of gear system that produces high reduction ratios in a compact size. It uses the mechanics of a flexible element deforming to transmit motion and achieve high precision and torque.

-

How does a harmonic gear box work?

+A harmonic gear box works by using a circular spline, flexspline, and a wave generator. The wave generator deforms the flexspline into an elliptical shape, which then engages with the teeth of the circular spline at two points, providing a high reduction ratio through the difference in tooth count between the engaged elements.

-

What are the main components of a strain wave drive?

+The main components are the circular spline (fixed outer ring), the flexspline (flexible inner ring with fewer teeth), and the wave generator (an elliptical disc that fits inside the flexspline).

-

What are the advantages of using harmonic/harmonic drive boxes?

+Strain wave/harmonic gearboxes offer high precision, zero backlashes, high torque capacity, compact size, and lightweight. They are also known for their excellent positional accuracy and repeatability.

-

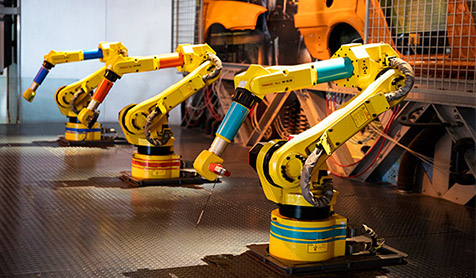

What applications are harmonic-type drives used in?

+They are used in applications requiring high precision and reliability, such as robotics, aerospace, defense, medical equipment, and semiconductor manufacturing equipment.

-

How do you select a strain wave drive for a specific application?

+Selection depends on factors like torque requirements, desired reduction ratio, space constraints, load capacity, and environmental conditions. It's essential to consult with manufacturers or experts to choose the appropriate model.

-

What are the different types of Strain Wave Gearboxes?

+Circular Spline Gearboxes

Cup-Type Gearboxes

Flat Gearboxes

-

What is a Circular Spline?

+The Circular Spline in Strain Wave Gearboxes are characterized by their robust design.

NEED A ONE-STOP SOLUTION?

We believe in delivering excellent customer service and we are dedicated to our customers.

If you want to know more about our products, prices, and customized services, please contact us with more details, we will respond as soon as possible.

Download

Download