You are here:

Difference Between Rotary Actuator and Motor

Views: 414

Author: Site Editor

Publish Time: 2024-04-20

Origin: Site

Rotary actuators and motors are two common mechanical devices that each play an important role in engineering and technical applications, but there are some significant differences in function and working principle.

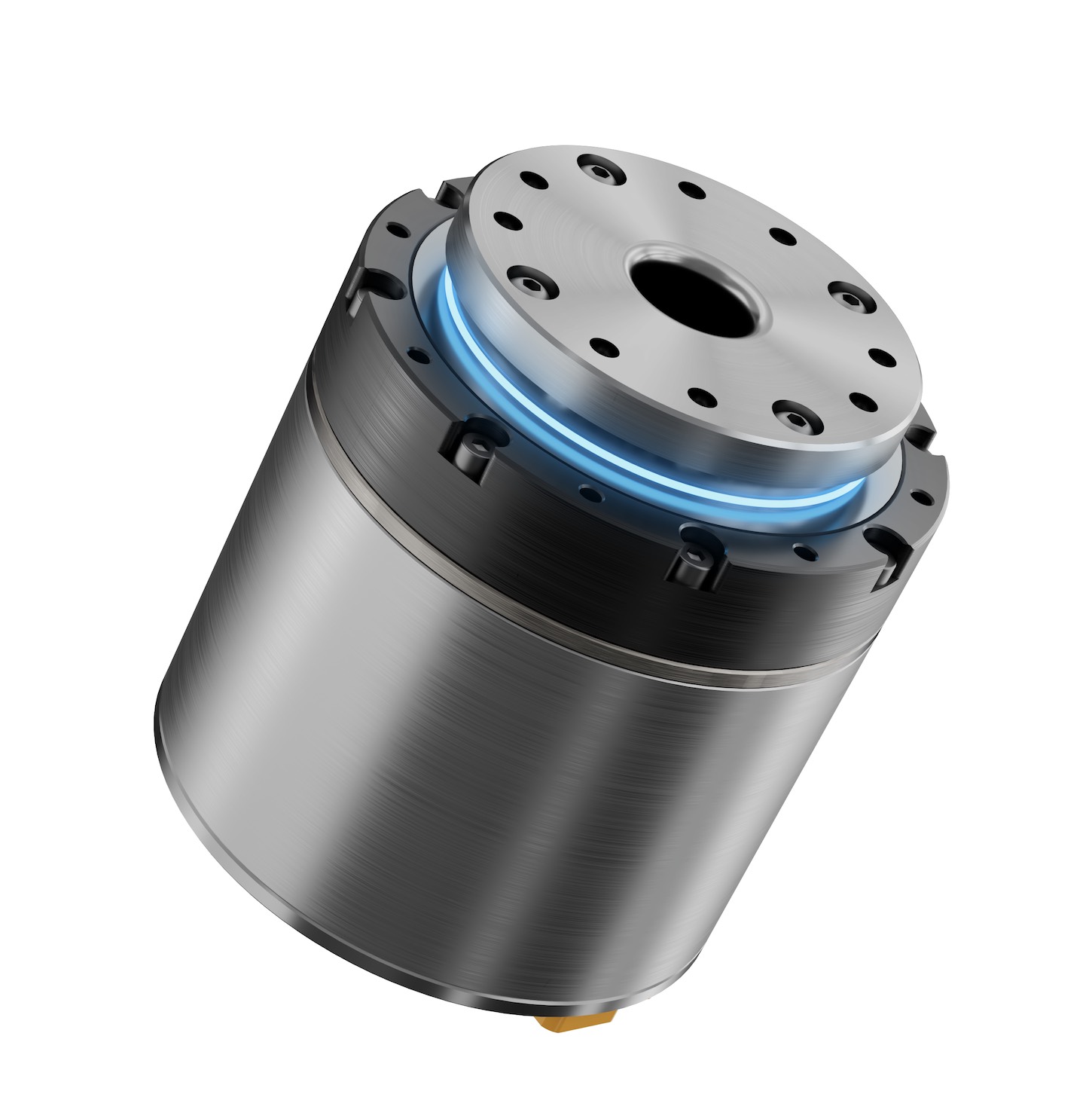

A rotary actuator is an actuator that produces a rotary motion or torque.It is usually composed of motor, reducer, encoder and other components, and is widely used in automation machinery, robots and other fields. The main feature of the rotary actuator is that it can achieve precise control of the rotating motion, and it is often used in occasions where large Angle rotation or precise positioning is required.

The motor is a device that converts electrical energy into mechanical energy, and generates rotational torque through the principle of electromagnetic induction to drive the load to rotate. Motors are widely used in various industrial and commercial fields, such as electric locomotives, household appliances, industrial machinery, etc. The main feature of the motor is that it can provide efficient mechanical power output, which is often used in situations requiring continuous operation or high-power output.

The motor is a device that converts electrical energy into mechanical energy, and generates rotational torque through the principle of electromagnetic induction to drive the load to rotate. Motors are widely used in various industrial and commercial fields, such as electric locomotives, household appliances, industrial machinery, etc. The main feature of the motor is that it can provide efficient mechanical power output, which is often used in situations requiring continuous operation or high-power output.

The difference between the rotary actuator and the motor is not only reflected in the function, control mode, structural design and output characteristics, but also can be considered from a more in-depth perspective.

The difference between the rotary actuator and the motor is not only reflected in the function, control mode, structural design and output characteristics, but also can be considered from a more in-depth perspective.

First of all, from the perspective of power transmission, rotary actuators usually achieve motion transmission through traditional mechanical transmission methods, such as transmission gear, belt and other transmission devices to transfer the power of the motor to the load parts. The motor directly converts electrical energy into mechanical energy through the principle of electromagnetic induction, thereby driving the load parts to achieve movement. This difference in transmission mode leads to certain differences in their application scope and efficiency.

Secondly, from the perspective of working principle and application field, rotary actuators pay more attention to precise control and adjustment of rotary motion, which is usually used in occasions where precise control of rotation Angle and speed is required, such as robot joints and automation equipment. The motor is widely used in a variety of occasions that require rotational movement, such as driving fans, pumps, conveyor belts, etc. Therefore, there are obvious differences between rotary actuators and motors in application fields and use scenarios.

In addition, from the perspective of technological development trends, with the continuous development of intelligent and automation technology, the demand for rotary actuators is growing, especially in the field of robotics and automation equipment. As a traditional power transmission equipment, the motor may be challenged by new devices such as rotary actuators in some specific application fields.

In general, there are obvious differences between rotary actuators and motors in terms of function, control mode, structural design and output characteristics. When choosing which equipment to use, it is necessary to consider factors such as specific application requirements, control requirements and working environment.

In general, there are obvious differences between rotary actuators and motors in terms of function, control mode, structural design and output characteristics. When choosing which equipment to use, it is necessary to consider factors such as specific application requirements, control requirements and working environment.

A rotary actuator is an actuator that produces a rotary motion or torque.It is usually composed of motor, reducer, encoder and other components, and is widely used in automation machinery, robots and other fields. The main feature of the rotary actuator is that it can achieve precise control of the rotating motion, and it is often used in occasions where large Angle rotation or precise positioning is required.

Main Differences

The main differences between rotary actuators and motors are reflected in the following aspects:- Function and application: Rotary actuator is a device whose main function is to generate rotary motion or torque according to the control signal for precise control of rotary action, which is commonly used in automated machinery, robots and other applications. The motor is a kind of equipment that converts electrical energy into mechanical energy, converts electrical energy into rotating torque through the principle of electromagnetic induction, drives the load to rotate, and is widely used in various industrial fields, such as fans, pumps, machine tools and so on.

- Control mode: The rotary actuator usually needs to accept external control signals (such as electrical signals, air pressure signals, etc.) to drive its internal mechanical structure, so as to achieve rotating action. The motor, on the other hand, can control its rotation direction and speed by changing the direction and size of the current.

- Structure and design: Rotary actuators may contain more complex mechanical structures to accommodate different control requirements. The motor usually includes the stator, rotor, commutator and other basic components, the design is relatively simple.

- Output characteristics: Rotary actuators are usually more focused on the control and adjustment of the rotating action, and their output may include precise rotation Angle, speed or torque. The motor is mainly concerned with the conversion efficiency of electric energy and the output of rotating torque.

First of all, from the perspective of power transmission, rotary actuators usually achieve motion transmission through traditional mechanical transmission methods, such as transmission gear, belt and other transmission devices to transfer the power of the motor to the load parts. The motor directly converts electrical energy into mechanical energy through the principle of electromagnetic induction, thereby driving the load parts to achieve movement. This difference in transmission mode leads to certain differences in their application scope and efficiency.

Secondly, from the perspective of working principle and application field, rotary actuators pay more attention to precise control and adjustment of rotary motion, which is usually used in occasions where precise control of rotation Angle and speed is required, such as robot joints and automation equipment. The motor is widely used in a variety of occasions that require rotational movement, such as driving fans, pumps, conveyor belts, etc. Therefore, there are obvious differences between rotary actuators and motors in application fields and use scenarios.

In addition, from the perspective of technological development trends, with the continuous development of intelligent and automation technology, the demand for rotary actuators is growing, especially in the field of robotics and automation equipment. As a traditional power transmission equipment, the motor may be challenged by new devices such as rotary actuators in some specific application fields.

×

×