Harmonic Drive: A Comprehensive Guide

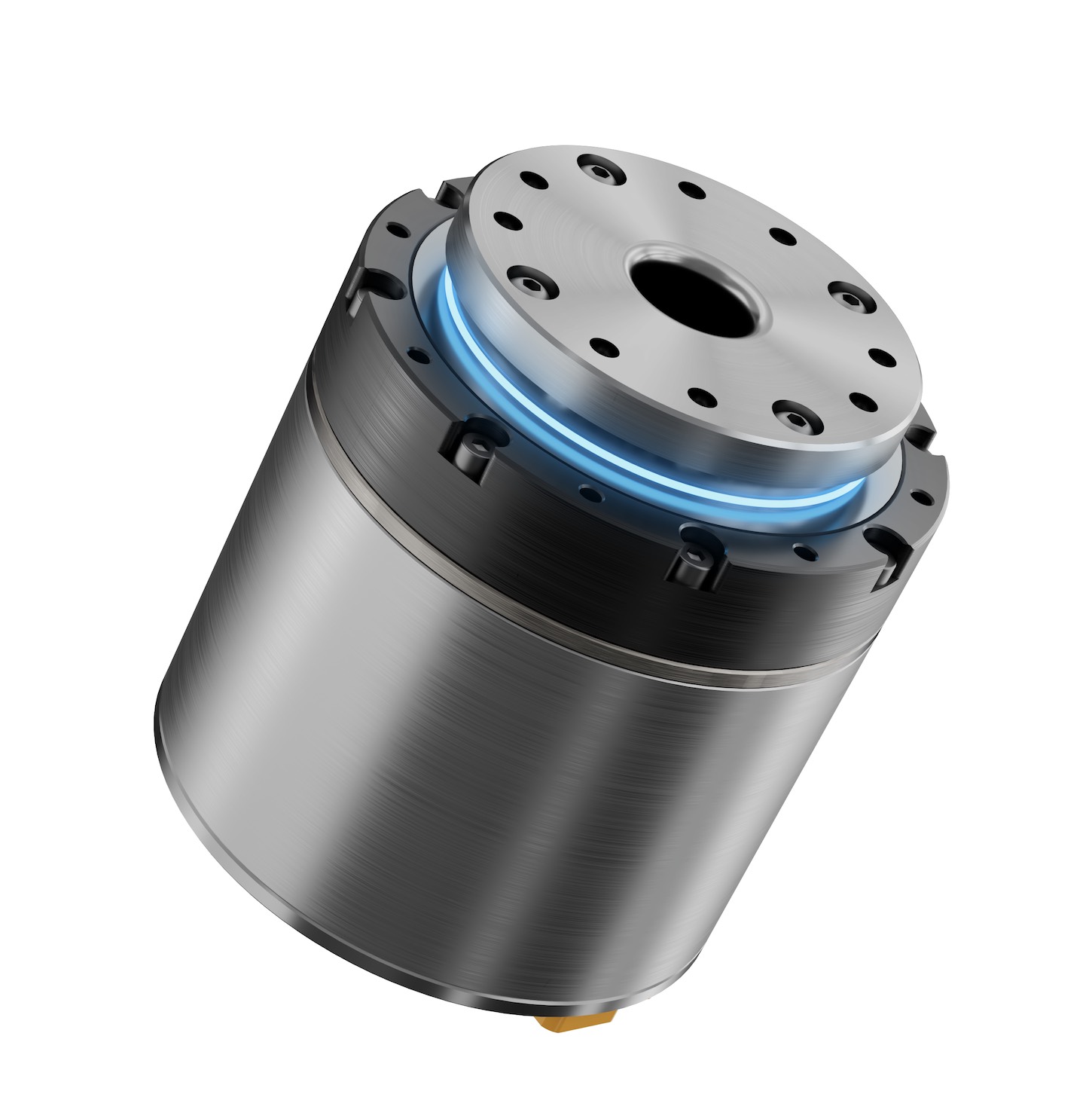

In the world of engineering and technology, there is always a need for high-precision and high-performance gear systems. One such system is the harmonic drive, also known as a strain wave gear, which has gained immense popularity over the years. This gear system features a unique design that allows for high precision, high torque, and low backlash.

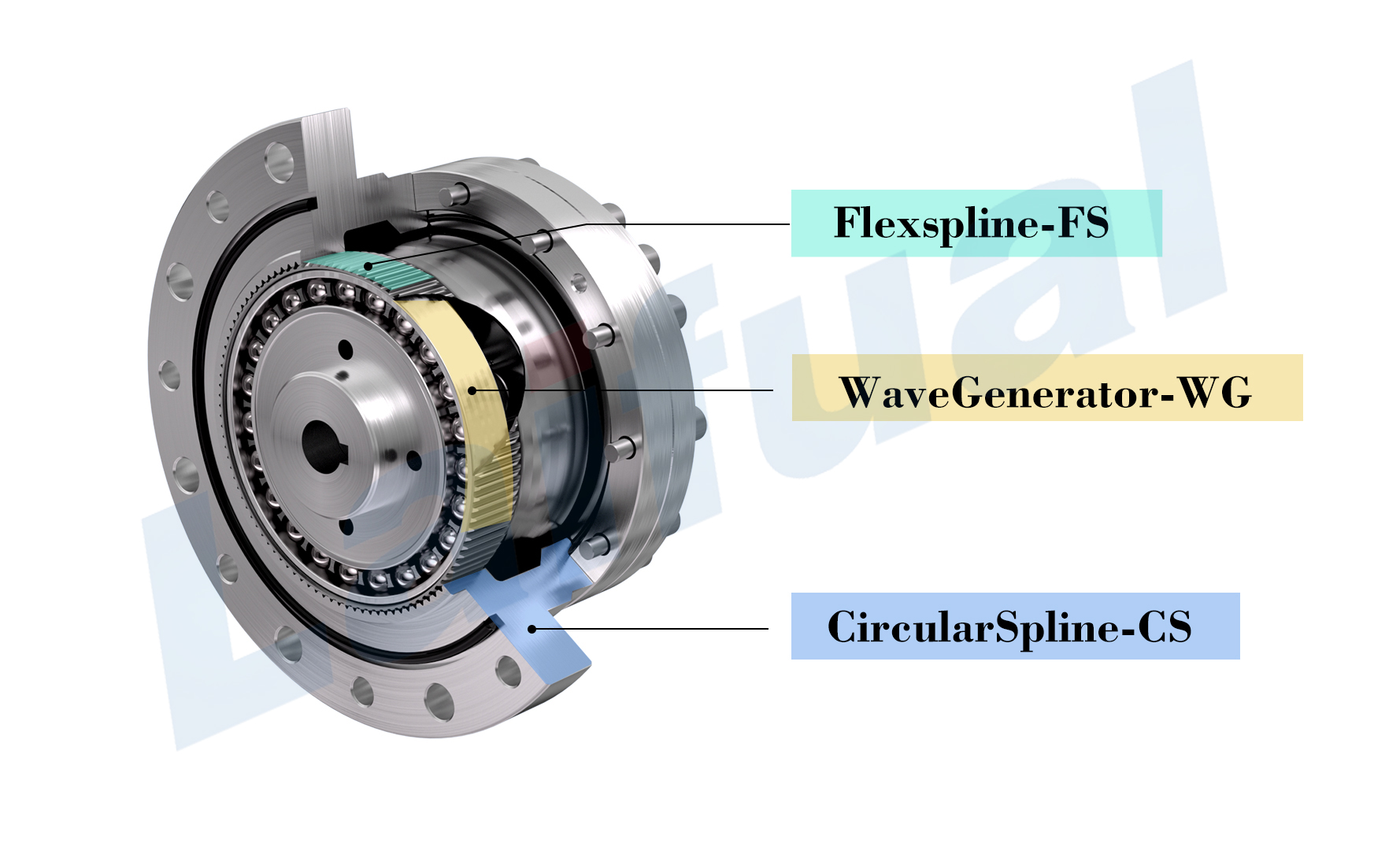

A harmonic drive consists of three main components: a circular spline, a flex spline, and a wave generator. The circular spline is a rigid ring with teeth on its inner diameter, while the flex spline is a thin-walled, cup-shaped component with teeth on its outer diameter. The wave generator is a metal component, typically a ball bearing assembly, that deforms into an elliptical shape when placed inside the flex spline.

When the wave generator rotates, it deforms the flex spline, causing its teeth to engage with the teeth of the circular spline. This engagement process results in precise and smooth rotational movement with minimal backlash. The harmonic drive's compact design and ability to provide high torque make it an ideal choice for applications in robotics, aerospace, and industrial automation where precision and performance are critical.

Working Principle of Harmonic Drive

The working principle of harmonic drive is based on the deformation of the wave generator. When the wave generator is rotated, it deforms the flex spline, causing the teeth on the flex spline to engage with the teeth on the circular spline. The deformation of the wave generator causes a reduction in the gear ratio, which results in high torque and low backlash.This structure not only can transmit high torque, but also has the characteristics of low backlash, ensuring high-precision motion control.

Advantages of Harmonic Drive

Harmonic drive offers several advantages over other gear systems, including:

- High Precision: Provides accurate positioning with minimal backlash.

- High Torque: Capable of delivering significant torque relative to its size.

- Compact and Lightweight: Efficient design that saves space and reduces weight.

- Smooth Operation: Ensures consistent and reliable movement.

- High Gear Ratios: Allows for significant speed reduction in a single stage.

- Durability: Long-lasting performance with minimal maintenance.

Applications of Harmonic Drive

Harmonic drive is used in a wide range of applications, including:

Robotics

Harmonic drive is widely used in robotics, especially in the arms and legs of humanoid robots. The high precision and low backlash of harmonic drive make it ideal for precise movements in robotics.

Harmonic drive is used in aerospace applications, including satellite positioning systems and antenna positioning systems. The lightweight and compact design of harmonic drive make it ideal for aerospace applications.

Harmonic drive is also used in medical equipment, including surgical robots and prosthetic limbs. The high precision and low backlash of harmonic drive make it ideal for delicate and precise movements in medical equipment.

Selection of Harmonic Drive

When selecting a harmonic drive, there are several factors to consider, including:

-

Required torque and speed

-

Operating environment

-

Required precision and accuracy

-

Cost

-

Lifespan

Maintenance of Harmonic Drive

To ensure the long lifespan and optimal performance of harmonic drive, regular maintenance is necessary. This includes regular inspection, cleaning, and lubrication.

Comparison with Other Gear Systems

Harmonic drive offers several advantages over other gear systems, including traditional gears and cycloidal gears. Compared to traditional gears, harmonic drive has a lower backlash and higher precision. Compared to cycloidal gears, harmonic drive has a higher torque and a more compact design.

Future of Harmonic Drive

The future of harmonic drive looks promising, with advancements in materials and manufacturing technology. New materials, such as composites, are being used in the manufacturing of harmonic drives, which can improve their performance and lifespan.

Harmonic drive is a highly precise and efficient gear system that has gained popularity in various industries, including robotics, aerospace, and medical equipment. Its unique design allows for high torque, low backlash, and compact design. While it has some disadvantages, such as high cost and limited lifespan, the advantages outweigh the disadvantages in many applications.