Harmonic Drives: Revolutionizing Precision Motion Control

In the world of motion control technology, harmonic drives have emerged as a crucial component for applications requiring high precision and compact design. These innovative devices are widely used in robotics, aerospace, and industrial automation, providing unparalleled performance and reliability. This article explores the advantages, types, applications, and success stories of harmonic drives, highlighting how they can elevate your operations.

What is a Harmonic Drive?

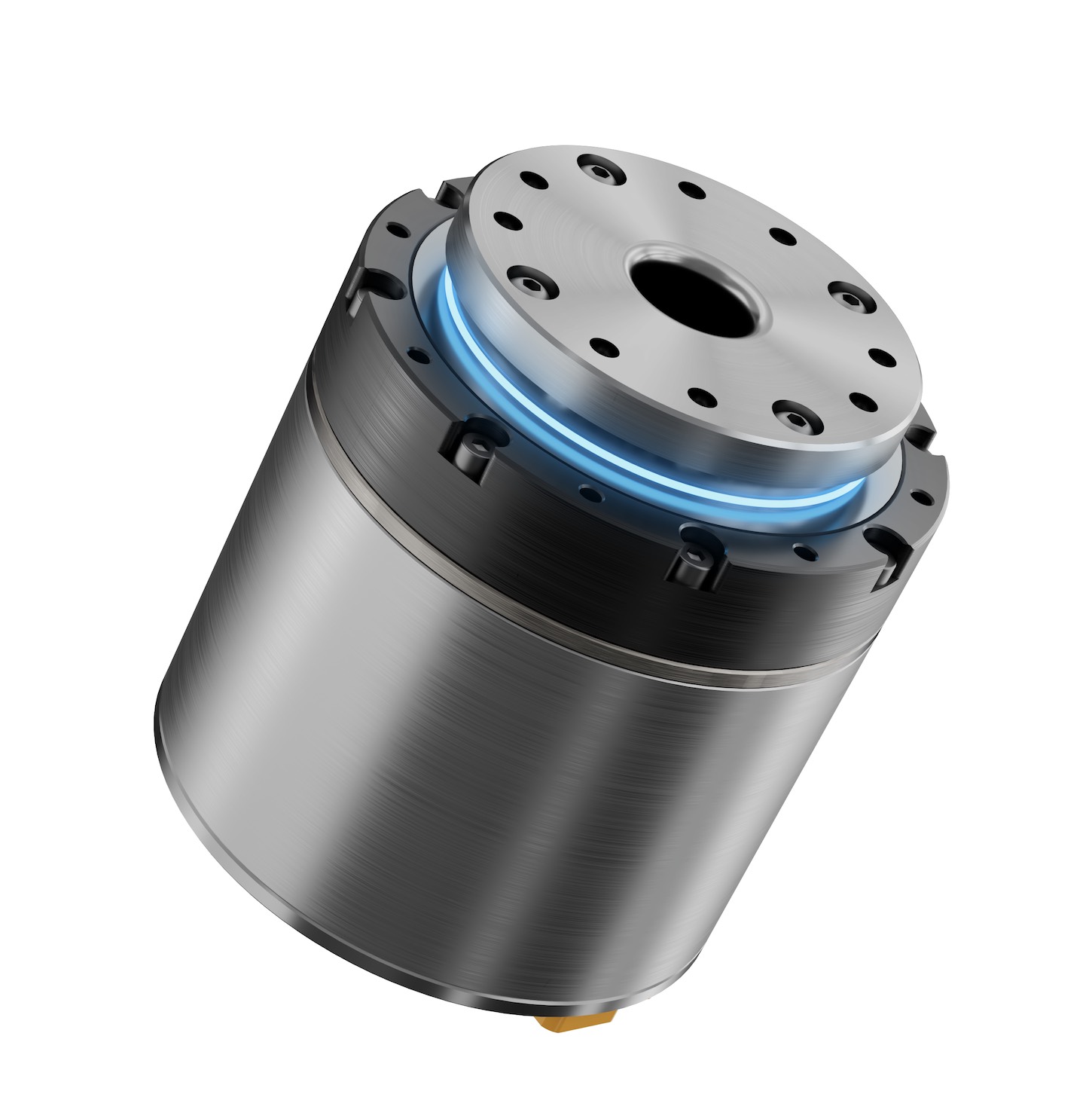

A harmonic drive is a type of gear mechanism that utilizes the unique properties of elastic deformation to achieve high reduction ratios and exceptional accuracy. It consists of three main components: a circular spline, an elliptical spline, and a wave generator. When the wave generator rotates, it deforms the elliptical spline, allowing it to engage with the circular spline and transmit motion with minimal backlash.

Advantages of Harmonic Drives

-

High Precision and Accuracy

Harmonic drives are known for their precise motion control capabilities. With backlash as low as 1 arc-minute, they provide accurate positioning, making them ideal for applications where precision is critical. -

Compact and Lightweight Design

One of the standout features of harmonic drives is their compact design. They offer high torque output in a smaller footprint, allowing for more efficient use of space in machinery and equipment. -

High Torque Capacity

Despite their small size, harmonic drives can handle high torque loads, making them suitable for heavy-duty applications. This capacity is essential in industries where heavy machinery must operate efficiently and reliably. -

Smooth Operation

The unique mechanism of harmonic drives allows for smooth and continuous motion. This characteristic is particularly beneficial in robotics and automation, where jerky movements can lead to errors and inefficiencies. -

Low Maintenance Requirements

Harmonic drives typically have a longer lifespan and require less maintenance than traditional gear systems. This reliability reduces downtime and maintenance costs for businesses.

Types of Harmonic Drives

At Laifual Group, we offer a variety of harmonic drives tailored to meet diverse industrial needs:

-

Standard Harmonic Drives

These are the most commonly used types, providing reliable performance across a range of applications. They are available in various sizes and reduction ratios to suit different requirements. -

Compact Harmonic Drives

Designed for applications with limited space, compact harmonic drives offer the same performance benefits in a smaller package. They are ideal for robotics and automation where size constraints are a factor. -

High-Torque Harmonic Drives

These drives are engineered to handle higher torque loads, making them suitable for heavy machinery and demanding industrial applications. Their robust design ensures reliable operation under pressure. -

Custom Harmonic Drives

For specialized applications, we provide custom harmonic drive solutions. Our engineering team works closely with clients to design drives that meet specific operational needs.

Applications of Harmonic Drives

-

Robotics

In robotics, precision is paramount. Harmonic drives are widely used in robotic arms, enabling accurate movement and positioning for assembly, welding, and other tasks. -

Aerospace

The aerospace industry demands high reliability and precision. Harmonic drives are utilized in control surfaces and landing gear systems, where accurate motion is critical. -

Medical Devices

In medical equipment, such as surgical robots and imaging systems, harmonic drives provide the precision needed for delicate procedures, enhancing patient safety and outcomes. -

Industrial Automation

Harmonic drives are integral to automated systems, including conveyor belts and packaging machines. Their ability to handle high speeds and precise movements improves overall efficiency. -

CNC Machinery

In computer numerical control (CNC) machines, harmonic drives ensure precise cutting and shaping of materials. This precision contributes to higher quality products and reduced waste.

Customer Success Stories

Many companies have experienced significant benefits by integrating harmonic drives into their operations. For instance, a leading robotics manufacturer reported a 40% increase in productivity after switching to our harmonic drives, thanks to their high precision and compact design. Additionally, an aerospace client noted a reduction in maintenance costs and improved reliability in their control systems after adopting our high-torque harmonic drives.

Why Choose Laifual Group’s Harmonic Drives?

When you select Laifual Group for your harmonic drive needs, you are choosing:

-

Expert Engineering Support

Our knowledgeable team is ready to assist you in selecting the right harmonic drive for your specific application, ensuring optimal performance. -

Quality Assurance

Our harmonic drives undergo rigorous testing to ensure they meet the highest industry standards for quality and reliability. -

Customization Options

We understand that every application is unique. Our custom solutions allow you to tailor harmonic drives to meet your specific operational requirements. -

Commitment to Innovation

We continually invest in research and development to provide cutting-edge solutions that enhance performance and efficiency in your operations.

Conclusion

Harmonic drives are transforming the landscape of motion control technology, providing businesses with the precision, reliability, and efficiency needed to excel in competitive industries. By choosing Laifual Group’s high-quality harmonic drives, you can improve operational efficiency, reduce maintenance costs, and achieve your business objectives. Contact us today to explore our range of harmonic drives and discover how we can support your success!