Integrated High Torque Robot Joint Module: A Comprehensive Overview

In the ever-evolving landscape of robotics, the demand for efficient and powerful components is paramount. The Integrated High Torque Robot Joint Module has emerged as a critical element for modern robotic applications , providing superior performance, versatility, and reliability. This article explores the significance, design, functionality, and applications of these modules, focusing on their role in enhancing robotic capabilities.

What is an Integrated High Torque Robot Joint Module?

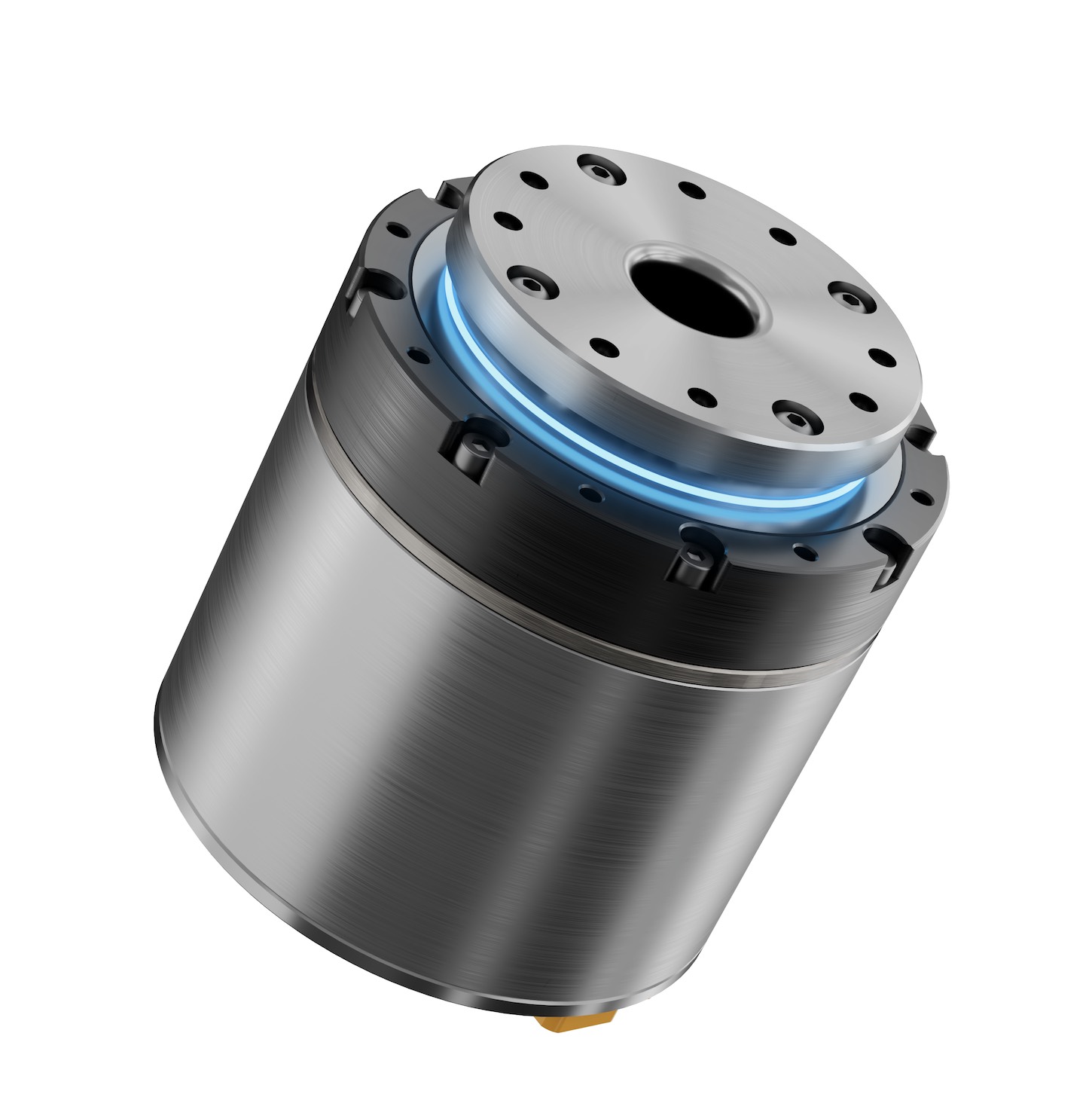

An Integrated High Torque Robot Joint Module is a sophisticated mechanical device designed to facilitate movement in robotic systems. This module is characterized by its ability to generate substantial torque while maintaining compact dimensions. It integrates various components, including motors, gears, and sensors, into a single unit, simplifying installation and reducing the overall footprint of robotic systems.

Key Components

- Motor: Provides the necessary power to generate movement.

- Gear System: Transmits and amplifies torque from the motor.

- Sensors: Offer feedback on position and torque, enhancing precision.

- Controller: Coordinates the operation of the module within the robotic system.

The Importance of Torque in Robotics

Torque is a crucial parameter in robotics, influencing the ability of a robot to perform tasks efficiently. Higher torque allows robots to handle heavier loads and execute complex movements. The Integrated High Torque Robot Joint Module meets this need by delivering enhanced torque capabilities, thereby expanding the range of applications for robotic systems.

Torque and Load Handling

In applications like industrial automation, robotic arms must lift and manipulate heavy objects. The torque provided by these modules is essential for overcoming inertia and friction, ensuring smooth operation even under challenging conditions.

Precision and Control

High torque modules allow for precise control over movements, essential in fields such as surgery or delicate assembly processes. The integration of sensors ensures that the robot can adjust its actions based on real-time feedback, improving accuracy.

Design Features of Integrated High Torque Robot Joint Modules

The design of these modules is driven by the need for efficiency and performance. Several features distinguish them in the market.

Compact Form Factor

Despite their powerful capabilities, these modules are designed to be compact. This feature enables their integration into various robotic systems without requiring excessive space.

Durability and Reliability

Manufactured using high-quality materials, the Integrated High Torque Robot Joint Modules are built to withstand the rigors of industrial environments. Their robust construction ensures longevity and reduces maintenance needs.

Versatile Mounting Options

These modules often come with multiple mounting configurations, allowing for flexible integration into diverse robotic architectures. This versatility is essential for engineers and designers looking to create customized solutions.

Applications of Integrated High Torque Robot Joint Modules

The applications of these advanced modules span multiple industries, showcasing their versatility and effectiveness.

Industrial Automation

In manufacturing environments, these modules are used in robotic arms and automated assembly lines. Their high torque capabilities enable them to handle heavy machinery and perform repetitive tasks with high precision.

Medical Robotics

In the medical field, high torque robot joints are critical for surgical robots. They allow for delicate movements required in procedures such as minimally invasive surgery, where precision is paramount.

Agricultural Robotics

Agricultural robots equipped with high torque modules can perform various tasks, from planting to harvesting. Their ability to exert substantial force allows them to interact with soil and crops effectively.

Service Robots

In service robotics, these modules enhance the functionality of robots used in hospitality, cleaning, and personal assistance. Their reliable torque output enables these robots to perform diverse tasks efficiently.

Technological Advancements

Recent advancements in technology have significantly improved the performance of Integrated High Torque Robot Joint Modules. Innovations in motor design, materials science, and control algorithms have led to modules that are not only more powerful but also more efficient.

Smart Control Systems

Modern robot joints often incorporate smart control systems that utilize machine learning algorithms. These systems allow robots to adapt to their environment, improving their efficiency and effectiveness in real-time.

Enhanced Feedback Mechanisms

The integration of advanced sensors provides better feedback on joint position and load conditions. This feedback is crucial for ensuring that the robot operates within safe parameters while maximizing performance.

Energy Efficiency

With growing concerns about energy consumption, many high torque modules are designed to be more energy-efficient. This focus on sustainability not only reduces operational costs but also minimizes the environmental impact of robotic systems.

Future Trends

The future of Integrated High Torque Robot Joint Modules is bright, with ongoing research and development paving the way for even more advanced systems.

Increased Automation

As industries continue to automate processes, the demand for high torque modules will likely rise. Future modules may incorporate even more sophisticated features to meet these needs.

Integration with AI

The incorporation of artificial intelligence into robotic systems will enhance their capabilities further. High torque modules will play a crucial role in enabling robots to learn from their experiences and improve their performance over time.

Expansion into New Industries

As robotics technology advances, we can expect to see these modules being utilized in new and innovative ways across various sectors, including entertainment, logistics, and more.

Conclusion

The Integrated High Torque Robot Joint Module is a vital component in the advancement of robotic technology. Its ability to provide high torque in a compact and reliable form factor makes it indispensable in numerous applications. As technology continues to evolve, these modules will play a crucial role in shaping the future of robotics, driving innovation, and expanding the possibilities of what robots can achieve.

FAQs

Q1: What is the main advantage of using an Integrated High Torque Robot Joint Module?

A1: The main advantage is its ability to provide substantial torque in a compact design, allowing robots to handle heavy loads and perform precise movements.

Q2: In which industries are these modules primarily used?

A2: They are primarily used in industrial automation, medical robotics, agricultural robotics, and service robots.

Q3: How do these modules enhance robotic precision?

A3: The integration of sensors in the modules allows for real-time feedback, enabling precise control over movements.

Q4: Are Integrated High Torque Robot Joint Modules energy-efficient?

A4: Yes, many modern modules are designed to be energy-efficient, helping to reduce operational costs and environmental impact.

Q5: What future trends are expected in the development of these modules?

A5: Future trends include increased automation, integration with AI, and expansion into new industries.

Q6: Can these modules be customized for specific applications?

A6:Yes, they often come with a variety of mounting options, allowing for customization to the specific needs of various robotic systems. If you have any needs, you can contact us and we will provide you with a free solution.

In conclusion, the Integrated High Torque Robot Joint Module represents a significant advancement in robotic technology, offering enhanced performance and versatility across multiple applications. As the field of robotics continues to grow, these modules will remain at the forefront, driving innovation and efficiency.