Understanding How Strain Wave Gears Work: A Deep Dive into Technology, Applications, and Advantages

Views: 568

Author: Site Editor

Publish Time: 2024-10-24

Origin: Site

Introduction to Strain Wave Gear Technology

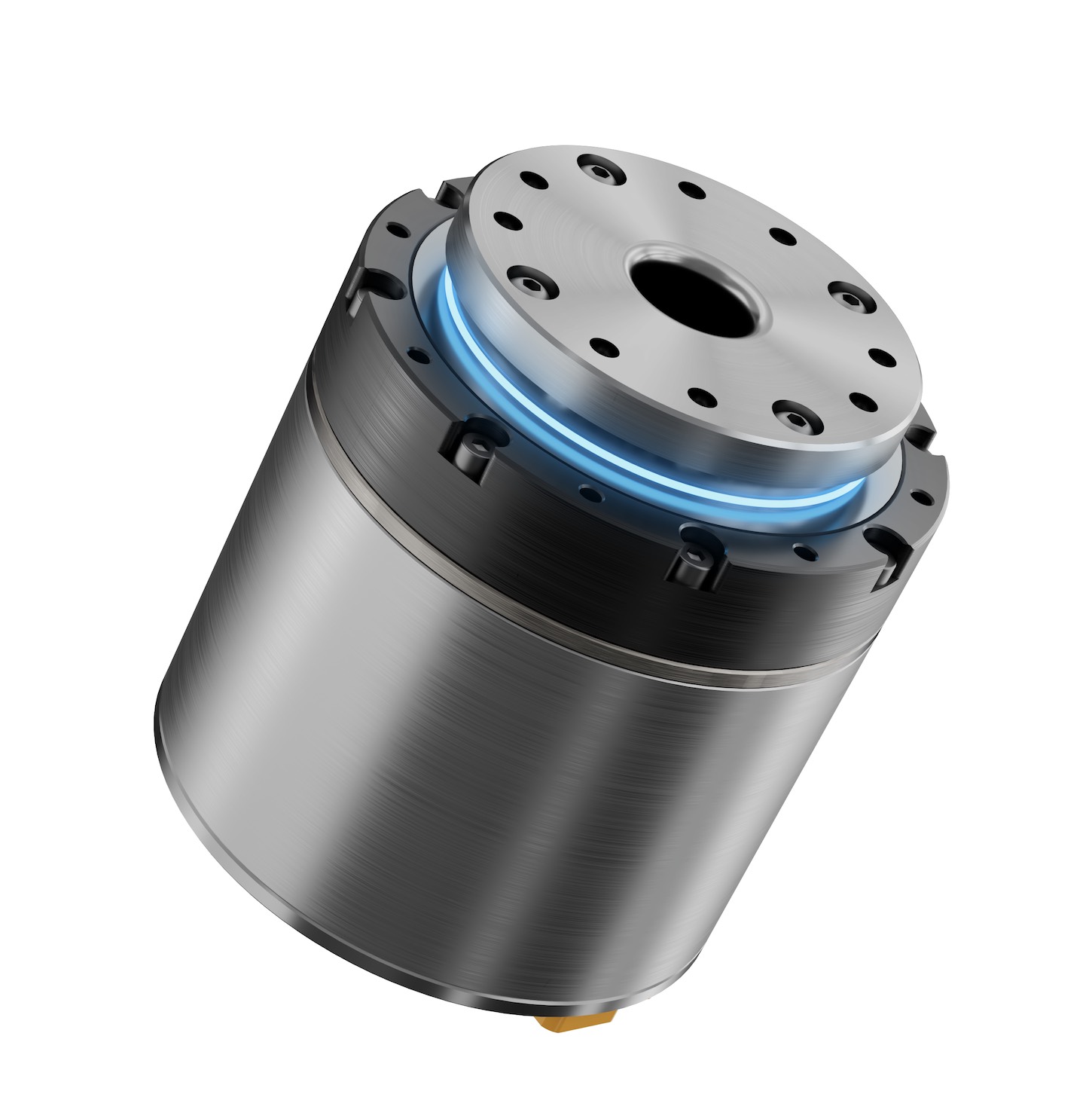

Strain wave gear , also known as harmonic drive, represents a remarkable innovation in the field of motion control. It offers unique benefits in precision, torque density, and compact design, which make it an ideal solution for industries like robotics, aerospace, and precision machinery. Originally developed in the 1950s, strain wave gearing technology has evolved, becoming integral in high-precision applications where conventional gear mechanisms fall short. This article explores the mechanics of strain wave gears, their advantages, and their applications in various industries.

How Does a Strain Wave Gear Work?

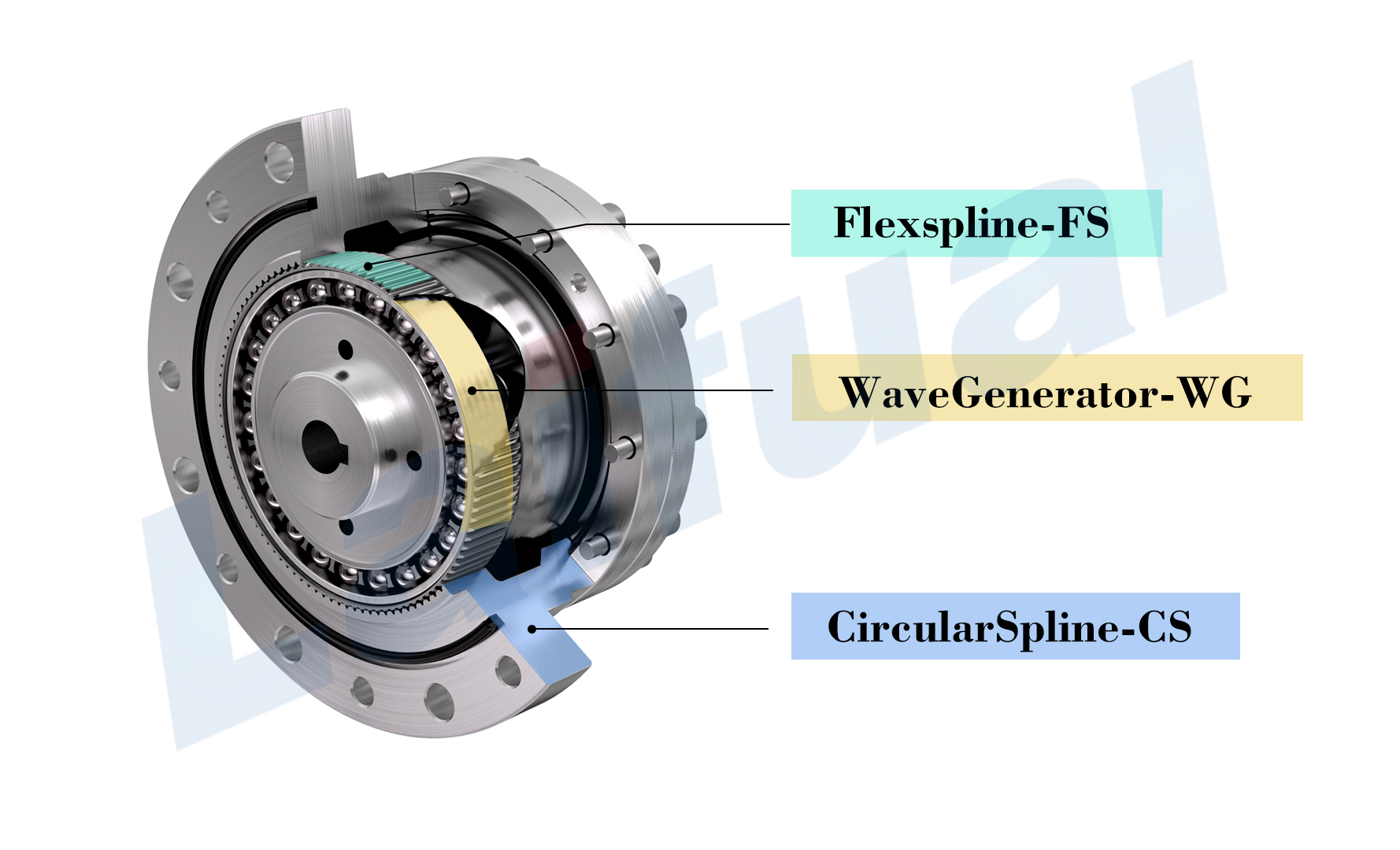

At the core, a strain wave gear operates using three main components: the **wave generator**, the **flexspline**, and the **circular spline**. The wave generator, a slightly oval-shaped metal disc fitted with a flexible bearing, is inserted into the flexspline, which is a thin, flexible, toothed cylindrical structure. The flexspline sits inside the circular spline, which has a rigid set of internal teeth.

Here’s a step-by-step breakdown of how strain wave gears produce motion:

- Wave Generation: The wave generator creates an elliptical shape when it rotates, causing the flexspline to deform and mesh with the circular spline at two opposite points. This flexing action is where the term "strain wave" comes from, as the gear relies on elastic deformation.

- Rotation and Torque Transfer: As the wave generator rotates, it deforms the flexspline, creating a rolling contact with the circular spline’s teeth. This deformation allows for torque transfer, where the flexspline "waves" move in one direction, effectively moving the flexspline’s teeth relative to the circular spline.

- Reduction Ratio: A key feature of strain wave gears is their high reduction ratios, achieved by having fewer teeth on the flexspline than on the circular spline. For example, if the flexspline has 200 teeth and the circular spline has 202, each rotation of the wave generator causes the flexspline to move two teeth backward, creating a reduction ratio of 100:1.

This process allows strain wave gears to produce high-torque output in a compact and lightweight structure, making them ideal for applications requiring precision and durability.

Key Components and Their Roles

Wave Generator

The wave generator is the primary driver of the flexspline’s movement. It transforms circular motion into the elliptical deformation necessary for gear reduction. This component is essential for the flexing action and ensures the strain wave effect, where small amounts of movement translate into high reduction ratios.Flexspline

Made from flexible materials, the flexspline is designed to bend without permanent deformation. Its toothed structure allows it to mesh with the circular spline only at specific points, enabling controlled movement and precise motion.Circular Spline

The circular spline remains stationary, providing the fixed internal teeth necessary for the reduction process. Its rigid design ensures it can handle significant torque while maintaining positional accuracy, even under heavy loads.Advantages of Strain Wave Gears

Strain wave gears offer unique benefits over conventional gear mechanisms, such as planetary gears and worm gears. These advantages include:

High Precision and Zero Backlash

Strain wave gears achieve near-zero backlash due to their unique design, which is crucial for applications requiring precise positioning, such as robotic arms and medical devices. The constant contact between the flexspline and circular spline teeth ensures high accuracy and prevents slippage.Compact and Lightweight

Due to their high reduction ratios, strain wave gears can achieve significant torque in a compact form. This compactness makes them ideal for applications where space is limited, like aerospace and robotics.High Torque-to-Weight Ratio

Strain wave gears offer one of the highest torque densities in gearing technology, making them efficient for applications requiring powerful torque outputs without heavy or bulky mechanisms.Excellent Efficiency and Durability

Strain wave gears have a smooth rolling motion that minimizes wear and tear, resulting in longer life and reduced maintenance needs. This durability is beneficial in industrial applications where gear replacement would be costly.Applications of Strain Wave Gears

The advantages of strain wave gears make them suitable for several high-precision and high-performance applications:

Robotics

In robotic arms and other precision-controlled robotic devices, strain wave gears provide the accuracy and repeatability required for smooth, controlled movements. With high reduction ratios and low backlash, these gears enable precise positioning critical for tasks like assembly, welding, and medical surgery.Aerospace and Defense

Strain wave gears are essential in aerospace applications , where weight and reliability are paramount. These gears contribute to mechanisms in satellites, aircraft control systems, and even space exploration equipment, where durability under extreme conditions and high efficiency are essential.Medical Equipment

In medical imaging and surgical robots, where precision is critical, strain wave gears allow for smooth, accurate motion control. They help reduce vibrations and unwanted movements, providing a safer and more precise experience in delicate surgical operations.Industrial Automation

Automation systems often require continuous, precise control in assembly lines and manufacturing. Strain wave gears support high-precision tasks in semiconductor manufacturing, CNC machinery, and inspection systems where positioning and accuracy cannot be compromised.Optics and Photonics

In telescope drives and camera gimbals, strain wave gears offer a high level of positioning precision with minimal vibration, which is essential for tracking and stabilizing optical equipment. Their compact size also makes them well-suited for handheld devices and portable equipment.Comparisons with Conventional Gear Mechanisms

When compared to other common gear types, strain wave gears have distinct advantages and some limitations:

- Planetary Gears: While planetary gears are effective for high-torque applications, they are generally bulkier than strain wave gears and may have slight backlash. Strain wave gears, by contrast, offer more compact solutions with minimal to no backlash, making them preferable for precision applications.

- Worm Gears: Worm gears provide high reduction ratios but at the cost of efficiency due to sliding contact. Strain wave gears, with their rolling contact, are more efficient and provide smoother motion.

- Spur and Helical Gears: These gears are common in many applications but are generally unsuitable for high precision tasks due to greater backlash. Strain wave gears, however, can handle precision with much greater ease and without compromising on torque or space.

Limitations of Strain Wave Gears

Despite their advantages, strain wave gears also have certain limitations:

Limited Speed Capacity: Strain wave gears are generally slower than other gear types due to their reliance on flexible materials. High-speed applications may exceed the flexspline’s material limits, causing wear over time.

Material Fatigue: The continuous flexing action can cause fatigue in the flexspline over extended use, leading to a reduced lifespan under high loads or long durations.

Cost: Manufacturing strain wave gears requires precision engineering and high-quality materials, making them more expensive than conventional gears.

Choosing the Right Strain Wave Gear for Your Application

Selecting a strain wave gear depends on factors like required torque, precision, speed, and environment. Here are some considerations:

- Load Requirements: For high-torque applications, a strain wave gear with a robust flexspline and rigid circular spline is recommended.

- Precision Needs: Applications requiring zero backlash, like medical and optical devices, benefit from high-quality strain wave gears.

- Environmental Conditions: For aerospace or underwater applications, materials resistant to temperature extremes and corrosion are necessary.

Future of Strain Wave Gear Technology

Advances in materials science and manufacturing techniques promise to enhance the capabilities of strain wave gears. Innovations such as carbon-fiber reinforced flexsplines, enhanced surface coatings, and hybrid materials could improve durability, reduce weight, and expand the range of applications. As automation and robotics become more integral to everyday operations, strain wave gears are likely to see increased demand and further technological refinement.

Conclusion

Strain wave gear technology exemplifies the power of engineering innovation in motion control, offering unmatched precision, torque density, and compactness. From robotics to aerospace, strain wave gears play a pivotal role in advancing precision and efficiency across industries. By understanding their mechanics, applications, and limitations, engineers can make informed decisions when selecting the right gear solutions for high-performance requirements. The future holds exciting possibilities for this unique technology, as it continues to shape the next generation of automation and control systems.

×

×