Precision Actuators: Enhancing Accuracy and Control in Modern Applications

Introduction to Precision Actuators

Precision actuators are critical components in a wide range of industries, from robotics and aerospace to medical devices and manufacturing. These actuators convert energy into precise mechanical motion, allowing for accurate control and movement in applications that require high levels of precision.

In this article, we'll explore what precision actuators are, their types, key applications, and the benefits they offer in modern technology.

What Are Precision Actuators?

Precision actuators are devices designed to provide controlled and exact movement in various mechanical systems. Unlike standard actuators, which may offer broader, less accurate motion, precision actuators are engineered to achieve highly accurate and repeatable positioning, often with tolerances in the micrometer or nanometer range.

These actuators are typically used in applications where exact positioning and smooth motion are critical, such as in the fields of robotics, aerospace, and medical technology.

Types of Precision Actuators

-

Linear Actuators:

Linear actuators convert rotational motion into linear motion, enabling precise control of position along a straight path. They are often used in applications like CNC machines, 3D printers, and robotic arms. Linear actuators can be further categorized into:- Ball Screw Actuators: Known for high precision and efficiency, often used in demanding industrial applications.

- Lead Screw Actuators: Provide high accuracy and are commonly used in applications requiring fine adjustments.

- Piezoelectric Actuators: Utilize the piezoelectric effect to achieve ultra-precise movements, often in the sub-micron range.

-

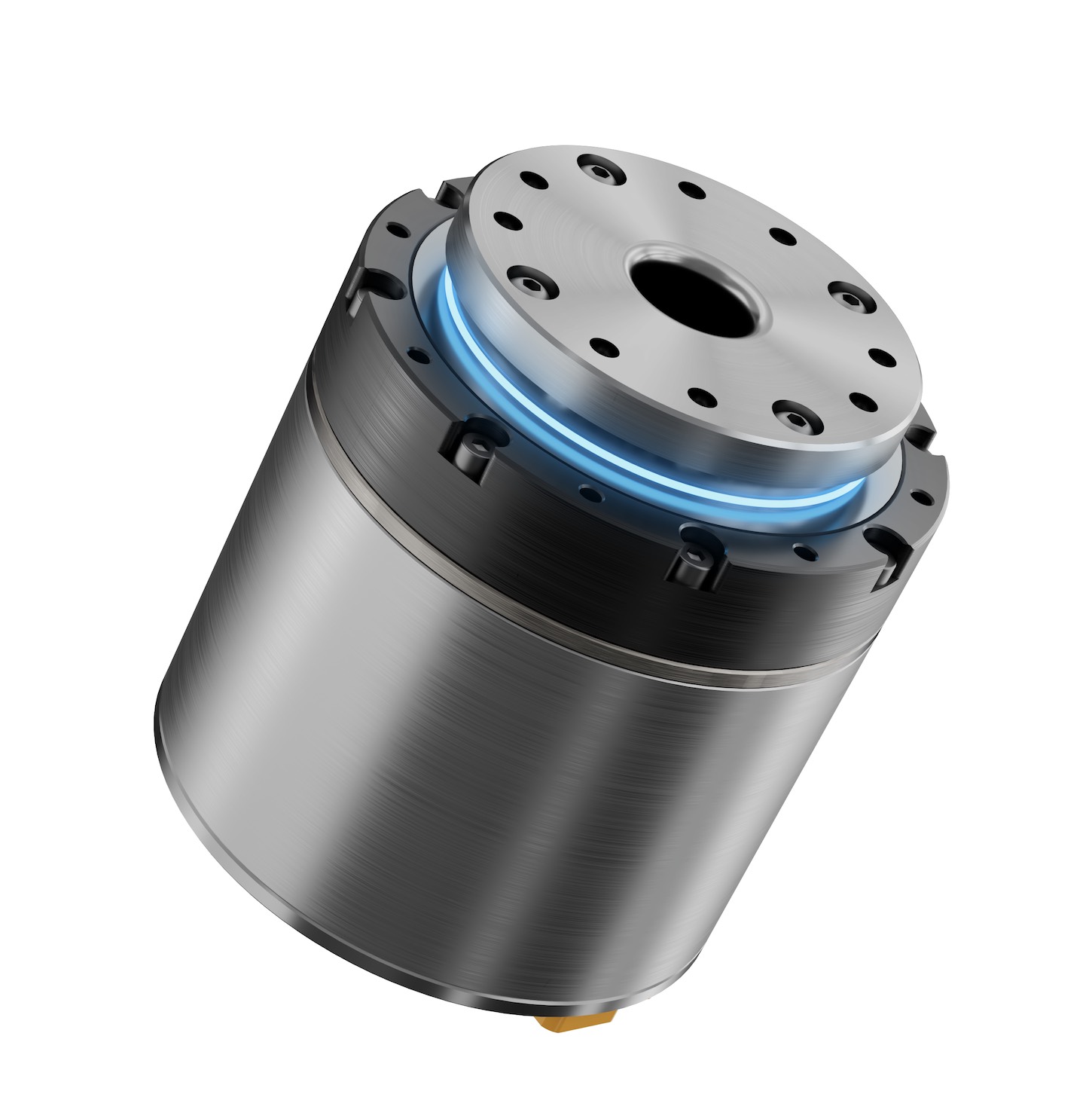

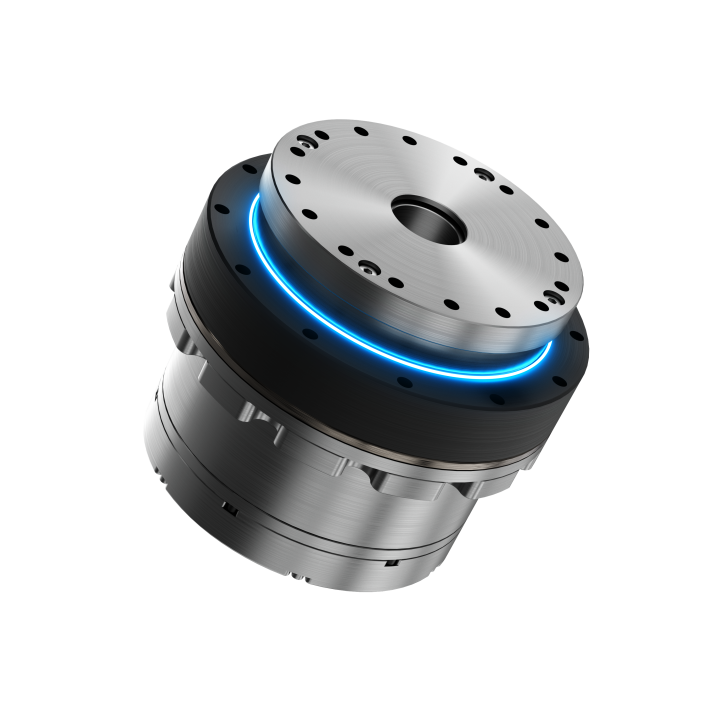

Rotary Actuators:

Rotary actuators control rotational movement, typically around a fixed axis. They are used in applications requiring precise angular control, such as in robotics and automated machinery. Common types include:- Servo Motors: Provide precise control of angular position, velocity, and acceleration.

- Stepper Motors: Operate in discrete steps, making them ideal for applications where exact positioning is required.

-

Voice Coil Actuators:

Voice coil actuators provide linear motion through electromagnetic induction. They are known for their high precision, fast response time, and smooth motion, making them ideal for applications like vibration control and optical focusing. -

Hydraulic and Pneumatic Actuators:

While traditionally less precise than electric actuators, advanced hydraulic and pneumatic systems can be engineered for high precision, particularly in heavy-duty applications where force and accuracy are both critical.

Applications of Precision Actuators

-

Robotics:

Precision actuators are fundamental in robotics, enabling exact movement and positioning of robotic arms, end-effectors, and other components. This precision is crucial for tasks such as assembly, welding, and material handling in automated systems. -

Aerospace:

In aerospace, precision actuators control the movement of control surfaces, landing gear, and other critical components. Their reliability and accuracy are essential for ensuring the safety and performance of aircraft. -

Medical Devices:

Medical technology often requires extremely precise movement, such as in surgical robots, diagnostic equipment, and prosthetics. Precision actuators enable these devices to perform delicate procedures with a high degree of control. -

Manufacturing:

In manufacturing, precision actuators are used in machinery for tasks like cutting, drilling, and assembly. They ensure that components are produced to exact specifications, improving product quality and consistency. -

Optics and Photonics:

Precision actuators are used in the alignment and positioning of optical components, such as lenses and mirrors. This is crucial in applications like microscopy, laser systems, and fiber optics, where even minute positioning errors can lead to significant performance degradation.

Benefits of Precision Actuators

-

High Accuracy and Repeatability:

Precision actuators offer unparalleled accuracy, ensuring that movements are consistent and repeatable, which is vital in applications where exact positioning is critical. -

Enhanced Control:

These actuators provide fine control over motion, allowing for smooth and precise adjustments. This is particularly important in applications like robotics and medical devices, where even small errors can have significant consequences. -

Reliability:

Precision actuators are designed for high reliability, ensuring consistent performance over time. This reliability is crucial in industries like aerospace and manufacturing, where downtime can be costly. -

Versatility:

Precision actuators can be used in a wide range of applications, from small-scale devices like medical instruments to large industrial machinery, making them a versatile solution for many different industries. -

Integration with Advanced Systems:

Precision actuators can be easily integrated with advanced control systems, including feedback mechanisms and sensors, to provide real-time monitoring and adjustment. This integration is essential for achieving high levels of automation and efficiency in modern systems.

Challenges and Considerations

-

Cost:

Precision actuators can be more expensive than standard actuators due to their advanced design and manufacturing processes. However, the benefits they offer often justify the higher cost in applications where precision is critical. -

Complexity:

The design and integration of precision actuators can be more complex, requiring careful consideration of factors like load, speed, and control systems. Proper design and testing are essential to ensure optimal performance. -

Maintenance:

While precision actuators are generally reliable, they may require more specialized maintenance due to their complexity and the need for exact calibration.

Conclusion

Precision actuators are a cornerstone of modern technology, enabling high accuracy and control in a wide range of applications. From robotics and aerospace to medical devices and manufacturing, these actuators play a crucial role in advancing technology and improving the efficiency and effectiveness of various systems. By understanding the different types of precision actuators and their benefits, engineers and designers can select the right components for their specific needs, ensuring optimal performance and reliability.