what is a servo actuator

A servo actuator is a device designed for precise control of the movement of mechanical components, widely used in various fields requiring accurate positioning, speed, and torque control. It consists of a motor, feedback sensors, and control circuitry, which work together to continuously monitor and adjust the system's output through a feedback mechanism to ensure high precision operation. Servo actuators are commonly found in automation systems, toys, household electronics, cars, and airplanes, where they control the movement or position of devices. Their high precision, quick response, and reliability make them an indispensable key component in complex applications.

How servo actuators work

Servo actuators are key components in automation technology, capable of converting electrical energy into precise controlled mechanical motion. Their working principle relies on a closed-loop control system, which consists of three basic parts: the controlled device, the output sensor, and the feedback system. When a reference input signal is applied to the system, it is compared with the system output signal detected by the output sensor, and a third signal is generated by the feedback system as the input signal for the controlled device. As long as there is a difference between the reference input signal and the output signal, the controlled device will adjust according to the third signal until the output reaches the expected value. At this point, the difference between the input and output disappears, and the device stops further operation until a new input signal arrives.

Servo systems achieve high-precision control of torque, speed, and position through this continuous feedback and adjustment. This dynamic response capability is crucial for applications that require high precision and repeatability, such as CNC machine tools and advanced robotic systems. The complex feedback loop of the servo actuator integrates sensors and advanced control algorithms to ensure that the system can adjust the output in real-time during operation, maintaining the desired system performance.

linear actuator vs servo actuator

A servo controller and an actuator are two distinct components in an automation system, each with different functions and roles.

-

Servo actuator

- Function: The servo controller is an electronic device responsible for controlling the operation of the servo system. It receives command signals from the control system and converts them into control signals sent to the actuator. The servo controller processes feedback signals (such as position, speed, and torque) and adjusts the actuator's output in real-time to ensure the system meets the desired performance criteria.

- Role: The servo controller acts as the "brain" of the servo system, maintaining accuracy and stability by continuously adjusting the output.

-

Actuator:

- Function: The actuator is a device that converts electrical signals into mechanical motion. It directly influences physical movements, such as rotation, linear motion, or other types of mechanical actions. Actuators can be electric, pneumatic, hydraulic, or other forms.

- Role: The actuator serves as the "muscle" of the servo system, executing mechanical actions according to the commands from the servo controller and driving the load.

The servo controller is the control unit that processes and transmits control signals to ensure the system operates as intended, while the actuator is the device that executes the mechanical actions, directly responsible for producing physical motion. Together, they form a complete servo system.

Components of a Servo Actuator

-

Motor: The motor is the primary driver in a servo actuator, typically an electric motor (DC or AC). It converts electrical energy into mechanical motion. The choice of motor depends on the application's requirements, with brushless DC motors being preferred for their efficiency and reliability.

-

Controller: The controller acts as the brain of the servo actuator. It receives input signals, processes them, and sends commands to the motor to achieve the desired motion. The controller can manage the motor's speed, position, and torque. Advanced controllers often incorporate microprocessors and sophisticated algorithms for enhanced performance.

-

Feedback Sensor: A key feature of servo actuators is their ability to provide precise control through feedback. Sensors like encoders or potentiometers measure the motor's actual position or speed, sending this data back to the controller. The controller then compares this information with the target value and adjusts the motor's operation to correct any discrepancies.

-

Drive Circuit: The drive circuit is responsible for delivering the appropriate power to the motor, based on the controller's commands. It modulates the voltage and current supplied to the motor, ensuring it operates within safe and efficient parameters.

-

Mechanical Components: Depending on the application, servo actuators may include gears, bearings, and other mechanical parts to translate the motor's rotational motion into the desired output. These components are crucial for achieving the necessary torque and speed.

Types of Servo Actuators

Servo actuators can be classified into various types based on different criteria, such as the type of motor used, the nature of motion, and the control method.

-

DC Servo Actuators: These actuators use direct current (DC) motors. They are known for their simplicity, ease of control, and wide range of applications. DC servo actuators are often used in small-scale and precise applications, such as robotics and medical devices.

-

AC Servo Actuators: Utilizing alternating current (AC) motors, these actuators are preferred in industrial settings where higher power and efficiency are required. AC servo actuators are robust, capable of handling large loads, and are commonly found in CNC machines, automated manufacturing systems, and conveyor systems.

-

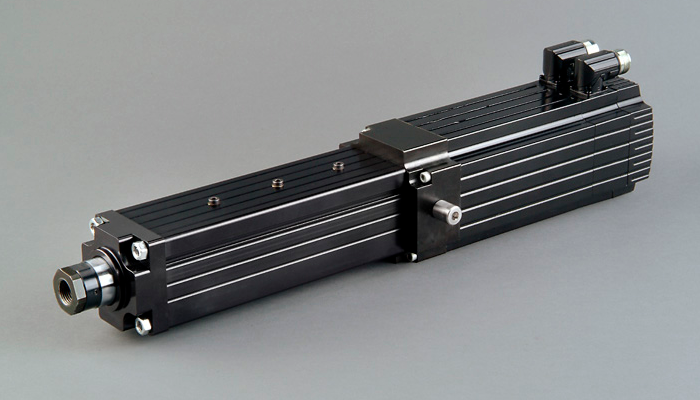

Linear Servo Actuators: While most servo actuators provide rotational motion, linear servo actuators convert this rotational motion into linear motion. They are ideal for applications requiring straight-line movement, such as in automation systems, robotic arms, and precision machining.

-

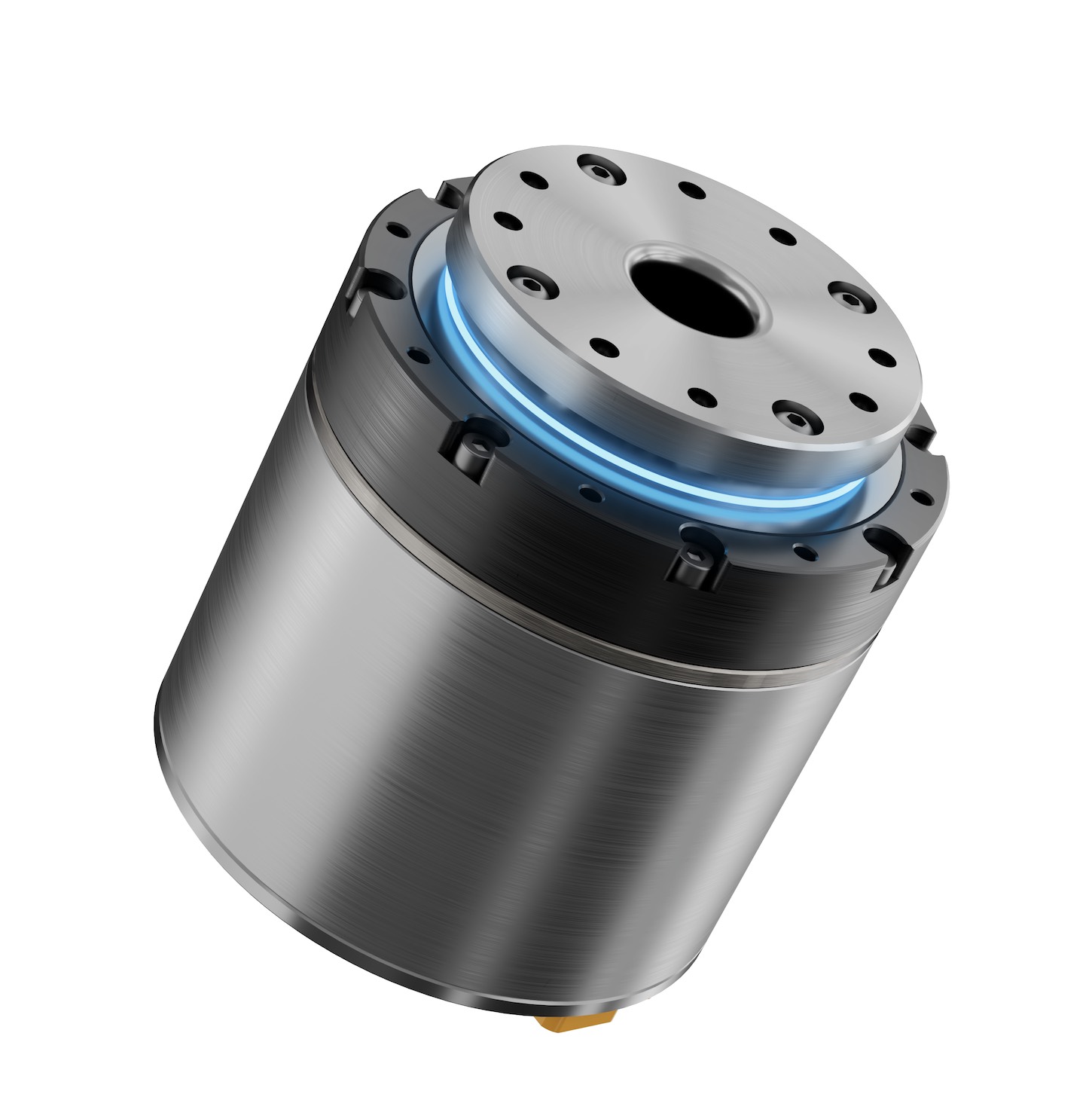

Rotary Servo Actuators: These are the most common type, providing rotational motion. They are widely used in various industries, from robotics to aerospace, where precise angular positioning is critical.

-

Digital Servo Actuators: Equipped with a digital controller, these actuators offer higher precision and faster response times compared to their analog counterparts. Digital servo actuators are essential in high-speed and high-accuracy applications, such as in aerospace and advanced robotics.

-

Analog Servo Actuators: These actuators use analog signals to control motion. While they offer less precision compared to digital types, they are simpler and less expensive, making them suitable for less demanding applications.

Applications of Servo Actuators

Servo actuators are used in a myriad of applications, owing to their versatility, precision, and reliability. Some of the most common applications include:

-

Robotics: In robotics, servo actuators control the movement of joints and limbs, enabling robots to perform complex tasks with high precision. From industrial robots on assembly lines to medical robots performing delicate surgeries, servo actuators are crucial for ensuring accurate and repeatable motions.

-

Aerospace: In the aerospace industry, servo actuators are used in flight control systems, where they control the movement of flaps, ailerons, and other critical components. Their ability to operate under extreme conditions while maintaining precision makes them ideal for this demanding sector.

-

Automotive: Servo actuators are widely used in automotive systems, including power steering, throttle control, and active suspension systems. Their ability to provide precise control enhances vehicle performance and safety.

-

Industrial Automation: In manufacturing and automation, servo actuators are employed in CNC machines, conveyor systems, packaging machines, and more. They ensure precise movement and positioning, critical for maintaining product quality and consistency.

-

Medical Devices: In the medical field, servo actuators are used in devices such as MRI machines, surgical robots, and infusion pumps. Their precision and reliability are vital for patient safety and the effectiveness of medical procedures.

-

Renewable Energy: In renewable energy systems, such as solar trackers and wind turbines, servo actuators play a key role in optimizing the position of panels and blades, maximizing energy capture.

Technological Advancements in Servo Actuators

The field of servo actuators has seen significant advancements, driven by the increasing demand for automation, precision, and energy efficiency. Some of the key trends include:

-

Miniaturization: With the advent of microelectronics, servo actuators are becoming smaller and more compact, without compromising on performance. This trend is particularly important in industries like robotics and medical devices, where space is at a premium.

-

Enhanced Feedback Mechanisms: Advanced feedback sensors, including optical encoders and resolvers, are improving the precision and reliability of servo actuators. These sensors provide more accurate and high-resolution data, enabling finer control over motion.

-

Smart Actuators: The integration of IoT (Internet of Things) technology is leading to the development of smart servo actuators that can communicate with other devices, perform self-diagnostics, and adapt to changing conditions in real time.

-

Energy Efficiency: Modern servo actuators are designed with energy efficiency in mind, using advanced control algorithms and materials to reduce power consumption. This is particularly important in applications where sustainability and cost reduction are key concerns.

-

Artificial Intelligence and Machine Learning: AI and machine learning are being integrated into servo control systems, enabling predictive maintenance, adaptive control, and optimization of performance over time. These technologies are making servo actuators smarter and more autonomous.

Servo actuators are the backbone of precision motion control in a wide range of industries. Their ability to provide accurate, reliable, and efficient control makes them indispensable in modern engineering and automation. As technology continues to advance, servo actuators will become even more sophisticated, offering new possibilities for innovation and efficiency. Whether in robotics, aerospace, automotive, or industrial automation, servo actuators will remain a critical component, driving the future of motion control.