Embracing the Future: The Role of 6-Axis Collaborative Robotic Arms and Harmonic Gear Reducers in Modern Automation

Views: 514

Author: Site Editor

Publish Time: 2024-06-13

Origin: Site

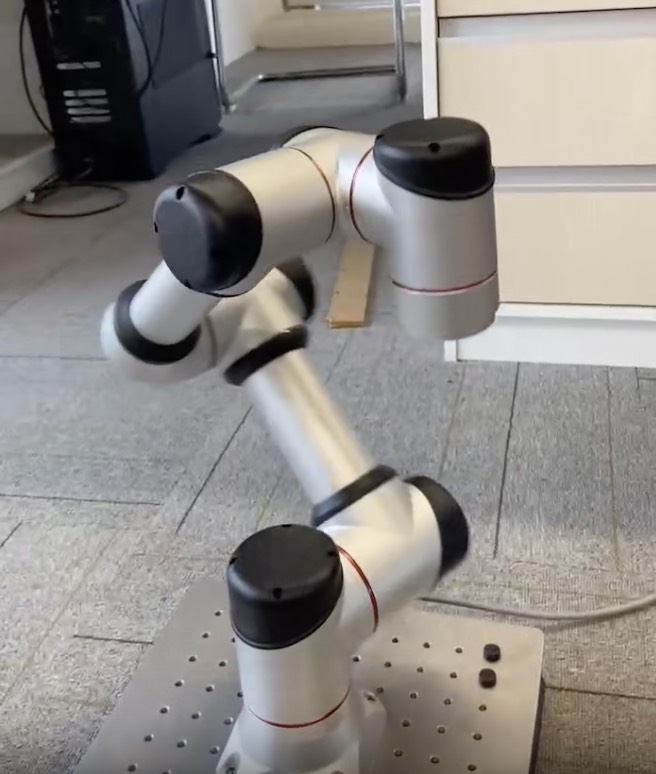

In the rapidly evolving world of automation and robotics, the 6-axis collaborative robotic arm stands out as a symbol of innovation and efficiency. These sophisticated machines, known for their flexibility and precision, are revolutionizing various industries by enhancing productivity and safety. A critical component driving their performance is the harmonic gear reducer, a technology that ensures smooth and accurate movements.

The Demand for 6-Axis Collaborative Robotic Arms

The global market for collaborative robots (cobots) is experiencing unprecedented growth. According to a report by MarketsandMarkets, the global cobot market size is projected to grow from USD 1.2 billion in 2020 to USD 7.5 billion by 2025, at a CAGR of 43.4%. This surge is driven by the increasing adoption of cobots across industries such as automotive, electronics, healthcare, and logistics.Cobots are designed to work alongside humans, enhancing the capabilities of the workforce rather than replacing it. The 6-axis collaborative robotic arm, with its six degrees of freedom, offers unparalleled flexibility and precision. These features make them ideal for tasks that require complex movements and high levels of accuracy, such as assembly, packaging, quality inspection, and surgical procedures.

Learn about laifualgroup’s detailed video on the 6-axis collaborative robotic arm

Applications of 6-Axis Collaborative Robotic Arms

Automotive Industry

: Cobots are transforming automotive manufacturing by performing tasks such as welding, painting, and assembly. Their precision and consistency reduce errors and improve product quality. According to the International Federation of Robotics (IFR), the automotive industry remains the largest user of industrial robots, accounting for nearly 30% of total installations.

Electronics Manufacturing

: In electronics, where precision and delicate handling are crucial, 6-axis cobots excel in assembling small components, soldering, and testing. Their ability to work in confined spaces without compromising accuracy makes them invaluable.

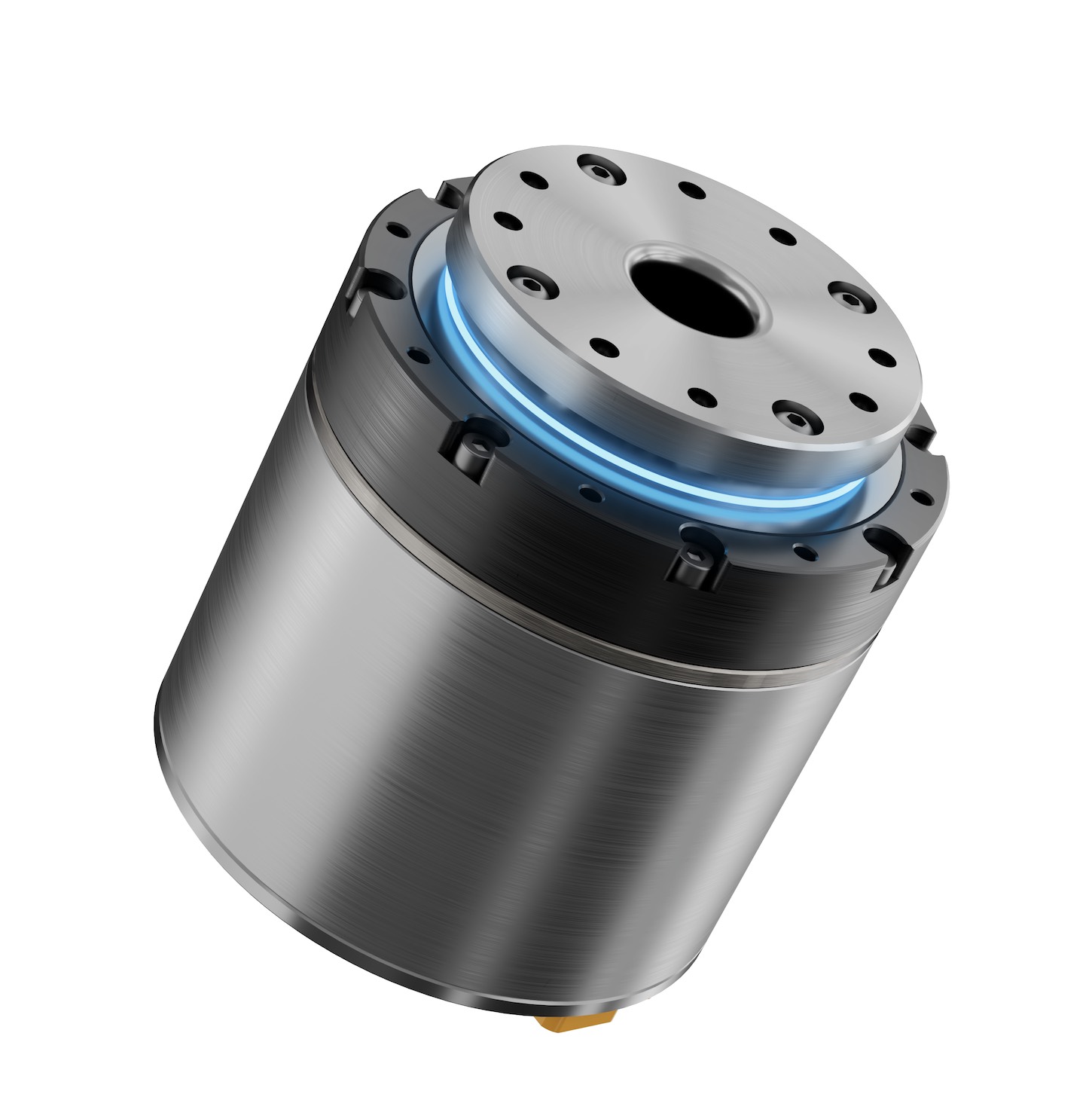

The Critical Role of Harmonic Gear Reducers

At the heart of these advanced robotic arms lies the harmonic gear reducer, a crucial component that ensures their smooth and precise operation. Harmonic gear reducers offer several advantages:- High Precision : Harmonic gear reducers provide exceptional positioning accuracy and repeatability, essential for tasks requiring meticulous movements.

- Compact and Lightweight : Their compact design allows for the creation of lightweight robotic arms without compromising strength or performance.

- Zero Backlash : The unique design of harmonic gear reducers eliminates backlash, ensuring smooth and consistent movements.

Laifual Harmonic Gear Reducers and Joint Modules

Laifual Drive, a leading manufacturer of harmonic gear reducers , offers products that are integral to the performance of 6-axis collaborative robotic arms. Laifual's harmonic gear reducers and joint modules are renowned for their high precision, durability, and efficiency. These products are designed to meet the rigorous demands of modern automation applications.Key Features of Laifual Harmonic Gear Reducers :

- High Torque Capacity : Capable of handling high loads, making them suitable for heavy-duty applications.

- Exceptional Durability : Built to withstand the harsh conditions of industrial environments, ensuring long service life.

- Smooth Operation : The zero-backlash design ensures smooth and precise movements, critical for high-precision tasks.

China's Robotics Export Landscape

China has emerged as a dominant player in the global robotics market. In 2022, China set a new record with 290,258 industrial robot installations, a 5% increase from the previous year. This growth underscores China's rapid advancements in robotics technology and its expanding manufacturing capabilities. The country's investment in industrial robots has resulted in high robot density, with 322 units per 10,000 employees in the manufacturing industry, surpassing the United States.Moreover, Chinese robot manufacturers like JAKA, Dobot, and Aubo are aggressively expanding their international presence, aiming to raise significant funds for global market penetration. These efforts are supported by a robust local supply chain and a growing ecosystem of robotics innovation.

Despite economic challenges, China's commitment to advancing its robotics industry remains strong, with ongoing investments in key components and multi-axis robots. This dedication ensures that China will continue to lead in the adoption and export of advanced robotics solutions.

Conclusion

The integration of 6-axis collaborative robotic arms into various industries is a testament to the advancements in robotic technology. The demand for these versatile and efficient machines is set to rise, driven by their ability to enhance productivity and safety across diverse applications. Harmonic gear reducers, such as those offered by Laifual Drive, play a pivotal role in the performance of these robotic arms, ensuring their smooth and precise operation.As industries continue to embrace automation, the synergy between advanced robotics and high-precision components like harmonic gear reducers will drive the future of manufacturing and beyond. Laifual Drive remains at the forefront of this technological revolution, providing innovative solutions that empower the next generation of robotic systems.

For more relevant professional data, please contact us

×

×