Guide to Choosing the Right Planetary Gear Reducer Manufacturers

Selecting the right planetary gear reducer manufacturers plays a pivotal role in enhancing operational efficiency and cost-effectiveness. These reducers boast an impressive efficiency of 98%, reducing complexity by 50% and size by 70%, while increasing load capacity by 300%. Such attributes make them indispensable in various applications. When choosing a manufacturer, consider factors like quality, reliability, and customization options. A well-chosen manufacturer ensures optimal performance and long-term value, making it crucial to evaluate their offerings meticulously.

Understanding Planetary Gear Reducers

What Are Planetary Gear Reducers?

Definition and basic components

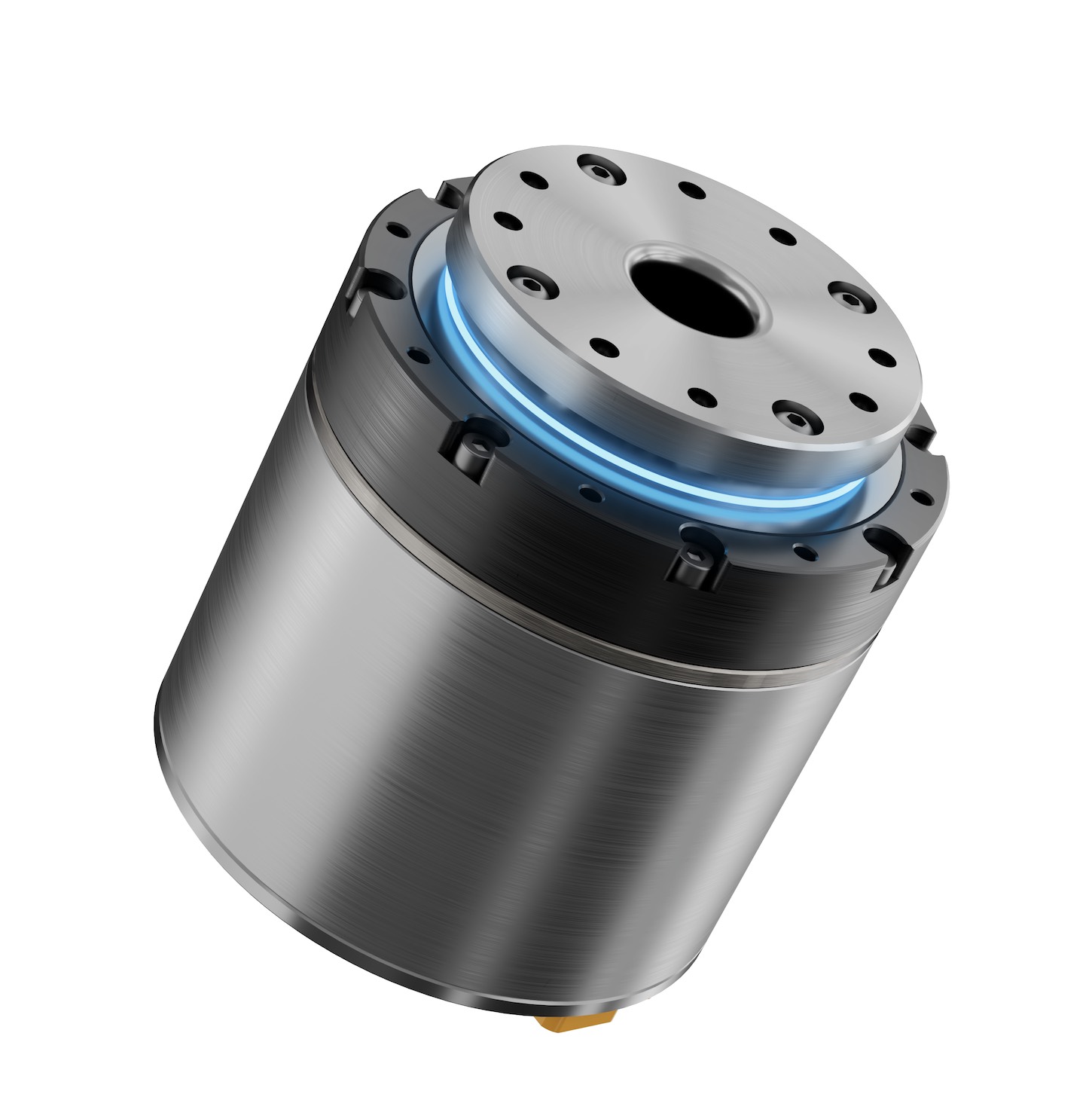

A planetary gear reducer is a sophisticated mechanical device designed to reduce the speed of input power while simultaneously increasing output torque. This mechanism resembles a solar system, where a central 'sun' gear interlocks with surrounding 'planet' gears, all encased within an outer 'ring' gear. This unique configuration allows for high torque output and compact size, making it ideal for applications requiring precision and efficiency.

How they work

The operation of a planetary gear reducer involves the interaction of its components. The sun gear, positioned at the center, drives the planet gears, which revolve around it. These planet gears are mounted on a movable carrier, which also rotates. The ring gear, which encases the entire assembly, remains stationary or rotates in the opposite direction. This arrangement provides multiple contact points, enhancing torque output and ensuring balanced weight distribution. The result is a high reduction ratio, maximizing torque while maintaining a compact design.

Applications of planetary gear reducers

Industrial applications

In industrial settings, planetary gear reducers play a crucial role in driving conveyor belts, mixers, and other machinery. Their high efficiency and durability make them indispensable in manufacturing plants, where they ensure reliable operations and minimal maintenance. The compact size of these reducers allows for easy integration into existing systems, optimizing space usage without compromising performance.

Automotive and aerospace uses

The automotive and aerospace industries also benefit significantly from planetary gear reducers. In electric vehicles, these reducers enhance torque output, improving acceleration and overall performance. In aerospace applications, their compact design and high precision make them suitable for adjusting satellite dishes and controlling robotic arms. The ability to deliver high torque in a small package makes planetary gear reducers a preferred choice for engineers and designers in these fields.

Key Factors in Choosing Planetary Gear Reducer Manufacturers

Quality and Reliability

Importance of high-quality materials

Planetary gear reducer manufacturers must prioritize the use of high-quality materials. These materials ensure durability and longevity, which are crucial for maintaining operational efficiency. High-quality materials reduce wear and tear, minimizing maintenance needs and extending the lifespan of the gear reducers. Manufacturers who invest in superior materials often deliver products that withstand rigorous industrial demands, providing a reliable solution for various applications.

Manufacturer's reputation and track record

A manufacturer's reputation serves as a testament to their reliability and quality. Prospective buyers should research the track record of planetary gear reducer manufacturers. A strong reputation often indicates consistent delivery of high-quality products and excellent customer service. Reviews and testimonials from previous clients can provide valuable insights into a manufacturer's performance. Additionally, industry certifications can further validate a manufacturer's commitment to quality and reliability.

Customization Options

Tailoring products to specific needs

Customization plays a vital role in meeting specific application requirements. Planetary gear reducer manufacturers offering tailored solutions can address unique operational challenges. Customization allows for adjustments in gear ratios, sizes, and configurations, ensuring optimal performance. Manufacturers that provide bespoke solutions demonstrate flexibility and a willingness to collaborate with clients to meet their precise needs.

Flexibility in design and production

Flexibility in design and production processes enables manufacturers to adapt to evolving market demands. Manufacturers with versatile production capabilities can quickly respond to custom orders and modifications. This adaptability ensures that clients receive products that align perfectly with their operational goals. Flexible manufacturers can also incorporate the latest technological advancements, enhancing the overall efficiency and effectiveness of their gear reducers.

Cost Considerations

Balancing cost with quality

Cost remains a significant factor when selecting planetary gear reducer manufacturers. However, buyers should not compromise quality for lower prices. A balance between cost and quality ensures that the gear reducers provide long-term value. Investing in high-quality products may involve higher initial costs, but it often results in reduced maintenance expenses and extended product life.

Long-term value and ROI

Evaluating the long-term value and return on investment (ROI) is essential when choosing a manufacturer. High-quality gear reducers typically offer better performance and durability, leading to increased ROI over time. Manufacturers that provide cost-effective solutions without sacrificing quality enable businesses to achieve greater operational efficiency and profitability. Assessing the total cost of ownership, including maintenance and potential downtime, helps in making informed purchasing decisions.

After-Sales Support

Availability of maintenance services

Planetary gear reducer manufacturers must offer comprehensive maintenance services to ensure the longevity and efficiency of their products. Regular maintenance prevents unexpected breakdowns and extends the lifespan of gear reducers. Manufacturers providing scheduled maintenance services demonstrate a commitment to customer satisfaction and product reliability. These services often include routine inspections, lubrication, and part replacements, which help maintain optimal performance. By offering such services, manufacturers ensure that their products continue to meet the high standards expected by their clients.

Customer service and technical support

Exceptional customer service and technical support are crucial for planetary gear reducer manufacturers. Clients rely on prompt and knowledgeable assistance to resolve issues and optimize the use of their gear reducers. Manufacturers with dedicated support teams can address inquiries and provide solutions efficiently. This level of support builds trust and fosters long-term relationships with clients. Technical support often includes troubleshooting, installation guidance, and performance optimization tips. By prioritizing customer service, manufacturers enhance their reputation and ensure client satisfaction.

Evaluating Planetary Gear Reducer Manufacturers

Research and Reviews

Evaluating planetary gear reducer manufacturers requires thorough research and analysis of customer feedback. Customer testimonials provide valuable insights into the performance and reliability of a manufacturer's products. Prospective buyers should seek out reviews from various sources to gain a comprehensive understanding of customer satisfaction levels. Positive testimonials often indicate a manufacturer's commitment to quality and customer service.

Industry certifications and standards serve as benchmarks for assessing a manufacturer's credibility. Certifications such as ISO 9001 demonstrate adherence to international quality management standards. These certifications assure buyers of the manufacturer's dedication to maintaining high-quality production processes. By prioritizing manufacturers with recognized certifications, buyers can ensure they are selecting a reputable and reliable partner.

Site Visits and Inspections

Conducting site visits and inspections allows buyers to assess the manufacturing facilities of planetary gear reducer manufacturers firsthand. Observing the production environment provides insights into the manufacturer's operational capabilities and quality control measures. Buyers should evaluate the cleanliness, organization, and efficiency of the facilities. A well-maintained facility often reflects the manufacturer's commitment to producing high-quality products.

Meeting with technical teams during site visits offers an opportunity to discuss specific requirements and assess the manufacturer's expertise. Technical teams can provide detailed information about the manufacturing process, customization options, and product specifications. Engaging with knowledgeable staff helps buyers gauge the manufacturer's ability to meet their unique needs. This interaction fosters a better understanding of the manufacturer's capabilities and builds confidence in their offerings.

Common Pitfalls to Avoid

Overlooking Long-Term Costs

Hidden costs in maintenance and repairs

Many businesses make the mistake of focusing solely on the initial purchase price of planetary gear reducers, neglecting the hidden costs associated with maintenance and repairs. These costs can accumulate over time, significantly impacting the total cost of ownership. Regular maintenance is essential to ensure the longevity and efficiency of gear reducers. However, unexpected repairs can arise, leading to additional expenses. Companies should consider these potential costs when evaluating planetary gear reducer manufacturers. By doing so, they can make informed decisions that align with their budgetary constraints and operational needs.

Ignoring warranty terms

Warranty terms play a crucial role in protecting investments in planetary gear reducers. Some manufacturers offer comprehensive warranties that cover parts and labor for a specified period. Others may provide limited coverage, leaving buyers responsible for certain repair costs. Understanding the warranty terms is vital to avoid unexpected expenses. Buyers should carefully review the warranty details provided by planetary gear reducer manufacturers. This ensures they receive adequate protection and support throughout the product's lifespan. A thorough understanding of warranty terms can prevent costly surprises and enhance overall satisfaction with the purchase.

Focusing Solely on Price

Risks of choosing the cheapest option

Opting for the cheapest planetary gear reducer may seem like a cost-effective decision initially. However, this approach often leads to subpar performance and increased maintenance costs. Low-cost options may use inferior materials, resulting in reduced durability and reliability. These products may fail to meet the rigorous demands of industrial applications, leading to frequent breakdowns and costly repairs. Businesses should prioritize quality over price when selecting planetary gear reducer manufacturers. Investing in high-quality products ensures long-term value and minimizes the risk of operational disruptions.

Importance of quality over cost

Quality should take precedence over cost when choosing planetary gear reducers. High-quality products offer superior performance, durability, and efficiency. They require less maintenance and provide a higher return on investment over time. Manufacturers that prioritize quality often use advanced materials and technologies, resulting in reliable and efficient gear reducers. By focusing on quality, businesses can achieve greater operational efficiency and reduce the likelihood of costly downtime. Selecting reputable planetary gear reducer manufacturers ensures access to products that meet industry standards and deliver consistent performance.

Choosing the right planetary gear reducer manufacturers is crucial for ensuring operational success and efficiency. Key factors such as quality, customization options, and after-sales support play a significant role in this decision-making process. Thorough research and informed choices help avoid pitfalls like hidden costs and inadequate warranties. Selecting a reliable manufacturer offers numerous benefits, including enhanced performance and long-term value. By prioritizing these considerations, businesses can secure a partnership that aligns with their operational goals and provides robust support throughout the product's lifecycle.